Effects of the length and spatial distribution of rapeseed straw returning field on corn sowing quality

-

摘要:

为降低长江中下游油菜-玉米轮作区油菜秸秆还田对玉米播种带来的不利影响,采用2因素10水平单因素试验,探究油菜秸秆长度(6~150 mm)及秸秆在不同深度土层(0~15 cm)的空间分布对玉米出苗率与植株高度等播种特性的影响。结果表明:玉米出苗率和植株高度随着油菜秸秆长度增大而逐渐减小,且呈线性关系,秸秆长度每降低1 cm,出苗率提高3.83个百分点,植株高度增加1.32 cm;当秸秆长度取最小值6 mm ,上层(≥0~5 cm)、中层(≥5~10 cm)和底层(≥10~15 cm)土层秸秆埋覆质量相同(秸秆质量变异系数为0)时,玉米出苗率达到100%,植株高度最大生长至55.84 cm;油菜秸秆长度相同、埋覆不均匀时,玉米出苗率和植株高度由上层土壤秸秆埋覆质量占比决定,且上层土壤秸秆埋覆质量占比越低,玉米出苗率和植株高度越高;当上层土壤秸秆埋覆质量占比相同时,玉米出苗率和植株高度由中层土壤秸秆埋覆质量占比决定,且中层土壤秸秆埋覆质量占比越低,玉米出苗率和植株高度越高;提高秸秆粉碎程度,降低中上层秸秆埋覆质量,增加底层土壤秸秆埋覆质量占比,实现秸秆深埋,有助于提高出苗率与植株高度。研究结果可为秸秆还田优质种床构建与质量提升提供理论支持。

Abstract:Rapeseed straw returning has been widely used in the rape-corn rotation area in the middle and lower reaches of the Yangtze River. However, there are adverse effects on the corn sowing quality at present. indicators are often used to evaluate the quality of straw return to the field, such as the coverage rate (the proportion of straw covering the surface) and burial rate (the proportion of straw buried in the soil). It is still unclear to fully express the spatial distribution of straw in the soil. In this study, a systematic investigation was implemented to explore the effects of length and spatial distribution on corn sowing quality in rapeseed straw returning. The corn germination rate and plant height were also taken as the evaluation indexes in the experiment. A 2-factor, 10-level, and one-way test was conducted to investigate the effects of rape straw length (6-150 mm) and the spatial distribution of straw in different depths of the soil (0-15 cm) on the corn emergence rate and plant height. The results showed that the emergence rate and plant height of maize decreased gradually and linearly with the increase in rape straw length. Specifically, the emergence rate and plant height increased by 3.83 percentage points and by 1.32 cm for every 1 cm decrease in straw length. The reason was that the long straw caused the soil to shelf, and the large void in the soil led to the aeration and breathability. The moisture conservation reduced emergence and survival rate during seeding and seedling rooting. The shorter the straw was, the greater the displacement of the straw movement was. Correspondingly, there was a higher decomposition rate of short straw than that of long one, indicating more contribution to mixing with the soil. The decomposition of nutrients promoted the development and growth of seedlings; Furthermore, the corn emergence rate reached 100%, and the plant height grew up to 55.84 cm when the length of the straw was taken as the minimum of 6 mm under the same straw mass of the upper (≥0-5 cm), middle (≥5-10 cm) and bottom (≥10-15 cm) straw, (coefficient of variation of the straw mass was 0). At the same time, the corn emergence rate and plant height were determined by the proportion of straw mass in the upper soil layer at the same length of rapeseed straw during uneven mulching. The greater corn emergence rate and plant height were achieved for the lower mass fractions of straw in the upper soil layer; Meanwhile, the corn emergence rate and plant height were determined by the proportion of straw mass in the middle soil layer, particularly in the same proportion of straw mulching mass in the upper soil layer. The smaller stover mass share was observed in the middle soil layer. There was a greater emergence rate and plant height of corn seedlings. The reason was that the straw stacking and clumping often occurred after returning the straw to the field and burying it in the shallow layer of soil because the straw and soil failed to mix sufficiently. The experiment demonstrated that the uniform spatial distribution of straw mass shared a significant effect on the seeding performance. However, there was no correlation between the uniform mulch and the performance of seeding. As such, the burying depth of straw greatly contributed to the water and fertilizer retention in the soil, even the distribution of roots. The continuous growth of roots promoted water and nutrients for the better growth of crops. The degree of straw crushing was improved to reduce the straw mass in the middle and upper layers. While there was an increase in the proportion of straw mass in the bottom layer of the soil. The deep burying of straw was realized to improve the seedling emergence rate and the height of the plant. The finding can provide theoretical support to construct high-quality seed beds for straw return.

-

Keywords:

- straw /

- corn /

- rapeseed /

- straw length /

- spatial distribution /

- sowing quality

-

0. 引 言

中国现有秸秆总量8.65亿t,其中玉米、小麦、水稻、油菜分别占33.99%、17.11%、24.39%、3.58%,如果能够进行肥化利用,相当于N、P、K肥

1572 万t,占国内施用肥料的30.28%[1-2]。随着化石燃料与电力能源逐渐取代秸秆焚烧成为农村居民日常生活的主要能源来源,加之作物密植增产及半喂入低损收获技术的推广应用,秸秆总量呈逐年递增趋势[3-6]。在国家颁发法律法规禁止焚烧秸秆和“绿水青山就是金山银山”的新时代背景下,秸秆还田以无污染、可循环、成本低的优点成为秸秆资源化利用的主要途径[7-8]。然而,大量秸秆混入土壤中影响土壤团粒结构与土壤耕层物理特性,对后茬作物造成不利影响。耕作区的大量秸秆会造成后茬作物耕播过程中种子架空,扎根不实、不牢,不出苗、出苗不齐、苗不直,开沟、旋耕等耕作部件拥堵等问题[9-11]。如何消除秸秆还田带来的影响已然成为一个社会热点问题。如何构建秸秆还田合理耕层,降低秸秆对后茬作物影响,对提升播种质量具有重要意义。

农艺试验表明,秸秆还田过程中秸秆粉碎长度、埋覆深度及秸秆在土壤中的分布等对秸秆腐解与种床质量具有显著影响。阳绪英[12]发现长度不超过10 cm的油菜秸秆比大于10 cm的油菜秸秆腐解速率快;庞荔丹[13]发现粉碎长度为3~5 cm的玉米秸秆腐解率高于5~10 cm的玉米秸秆。当秸秆粉碎长度超过10 cm时,耕翻入土的长秸秆会造成土壤架空,大的空隙会导致通风透气,难以达到保墒的目的,影响播种和幼苗扎根,造成出苗率和成活率下降。徐高明等[14]发现秸秆长度越短,秸秆运动位移越大,越有利于与土壤的混合。可见秸秆粉碎越短,腐解越快,对土壤耕层特性影响越小。

胡宏祥等[15]发现还田深度在5 cm时的水稻秸秆腐解速度要快于10 cm深还田和表层还田。若还田后秸秆埋入土壤浅层,会导致秸秆与土壤不能充分混合,出现秸秆堆叠和成团现象,使得表层土壤过于疏松,耕作层比较浅,直接影响下茬作物的插栽和播种质量。KONG等[16]发现秸秆还田深度25~28 cm有利于水稻植株生根分蘖。秸秆深埋还田能够有效提高土壤的保水、保肥和供肥能力,同时也可促进根系的分布,而根系的连续生长可促进水分和养分的吸收,利于作物生长 [17]。提高秸秆埋覆深度,有助于提升种床质量。

秦宽等[18]发现还田过程中保持粉碎抛撒均匀可使秸秆全量还田的同时提供良好的免耕播种环境。田仲和等[19]进行了麦秸不均匀还田的微区试验,结果表明,局部地段秸秆堆积会导致还田物质过多积累,严重影响稻种出苗、成苗,对水稻的苗期生长也有一定影响。顾峰玮等[20-21]发现秸秆埋覆不均易导致种子播在秸秆上,造成架种,覆土不可靠,易造成晾种。范围等[22]试验发现秸秆均匀还田明显降低土壤容重和土壤坚实度,增加土壤有机碳含量,有效促进秸秆的腐解和转化,促进土壤腐殖质积累,显著提高玉米产量。可见,提升秸秆还田均匀性,有助于构建适宜种床,促进作物萌发生长[23]。

综上所述,秸秆粉碎长度越短,埋覆越深,与土壤混合越均匀,越有利于加速秸秆腐解,降低秸秆还田对后茬作物的影响。但秸秆还田过程中,不同深度土壤秸秆质量占比随埋覆深度的增加而降低[24],秸秆与土壤完全均匀混埋难以完全实现。同时,秸秆粉碎长度对秸秆在土壤中的质量分布具有显著影响。根据秸秆粉碎长度与其在土壤中的质量分布特征对后茬作物的影响规律,采用秸秆粉碎与埋覆部件对秸秆进行粉碎与分布调整,对提高秸秆还田播种质量具有重要意义。

本研究针对长江中下游油菜-玉米轮作区油菜秸秆还田对玉米播种带来的不利的影响,结合油菜秸秆留茬高、秆茎粗、腐解难的特点,以秸秆粉碎长度和秸秆在不同深度土层中的质量占比为试验因素,以玉米出苗率与植株高度为试验指标,采用单因素试验,建立油菜秸秆还田长度和空间分布与玉米播种质量关系,以期为秸秆还田优质种床构建与质量提升提供理论支持。

1. 材料与方法

1.1 试验材料

试验于2023年5月1日在长江中下游油菜-玉米轮作区展开,试验地位于湖北省农科院鄂州基地(30°23′N,114°39′E),该地区属于亚热带大陆性季风气候,年降水量1 315 mm,年均气温17 ℃,无霜期年均266 d。试验地块为潮土,具有腐殖质层(耕作层)、氧化还原层及母质层等剖面层次,沉积层理明显。经测量,深度≥0~5、≥5~10和≥10~15 cm的土壤质量含水率分别为10.99%、11.78%和12.44%,土壤坚实度为2.36、3.60和5.02 MPa;试验地单位面积油菜秸秆质量平均值为

1194.2 g/m2。试验玉米品种为昊甜168,根据玉米种植密度4.5~6万株/hm2、播深3~5 cm的农艺要求,确定种行距为50 cm、株距为33 cm、播深为4 cm。为提高土壤的保墒能力,并防止玉米种子被虫鸟啄食,播种后对试验田块进行铺膜处理。1.2 试验因素与水平

根据DB21/T2513-2015双轴灭茬旋耕机作业技术规范,秸秆还田深度定为15 cm,每组试验田块大小为1 m(长)×1 m(宽)×15 cm(深)。试验地油菜秸秆经过测量为

1194.2 g/m2,为方便试验操作,取近似值1200 g/m2,将单位平米试验田块还田秸秆量平均分成6份(每份200 g)。为确定秸秆埋覆均匀性对试验结果影响,将秸秆按质量比为1:2:3、1:1:4和2:2:2埋至≥0~5、≥5~10和≥10~15 cm 三层土壤中,对应的秸秆埋覆质量变异系数分别为50%、86.6%和0。在秸秆埋覆质量变异系数为50%时,按照1:2:3质量比埋入3层土壤中的有6种组合,按照1:1:4质量比埋入3层土壤中的有3种组合,按照2:2:2质量占比埋入土壤中的只有1种组合,因此设置10个不同深度土层秸秆埋覆质量占比。按照DB34/T1090-2009稻油轮作两熟制秸秆还田机械化作业技术规范,将油菜秸秆粉碎长度范围定为6~150 mm,设置为等间距的10个水平,试验因素与水平如表1。表 1 试验因素与水平Table 1. Experimental factors and levels水平Level 秸秆长度

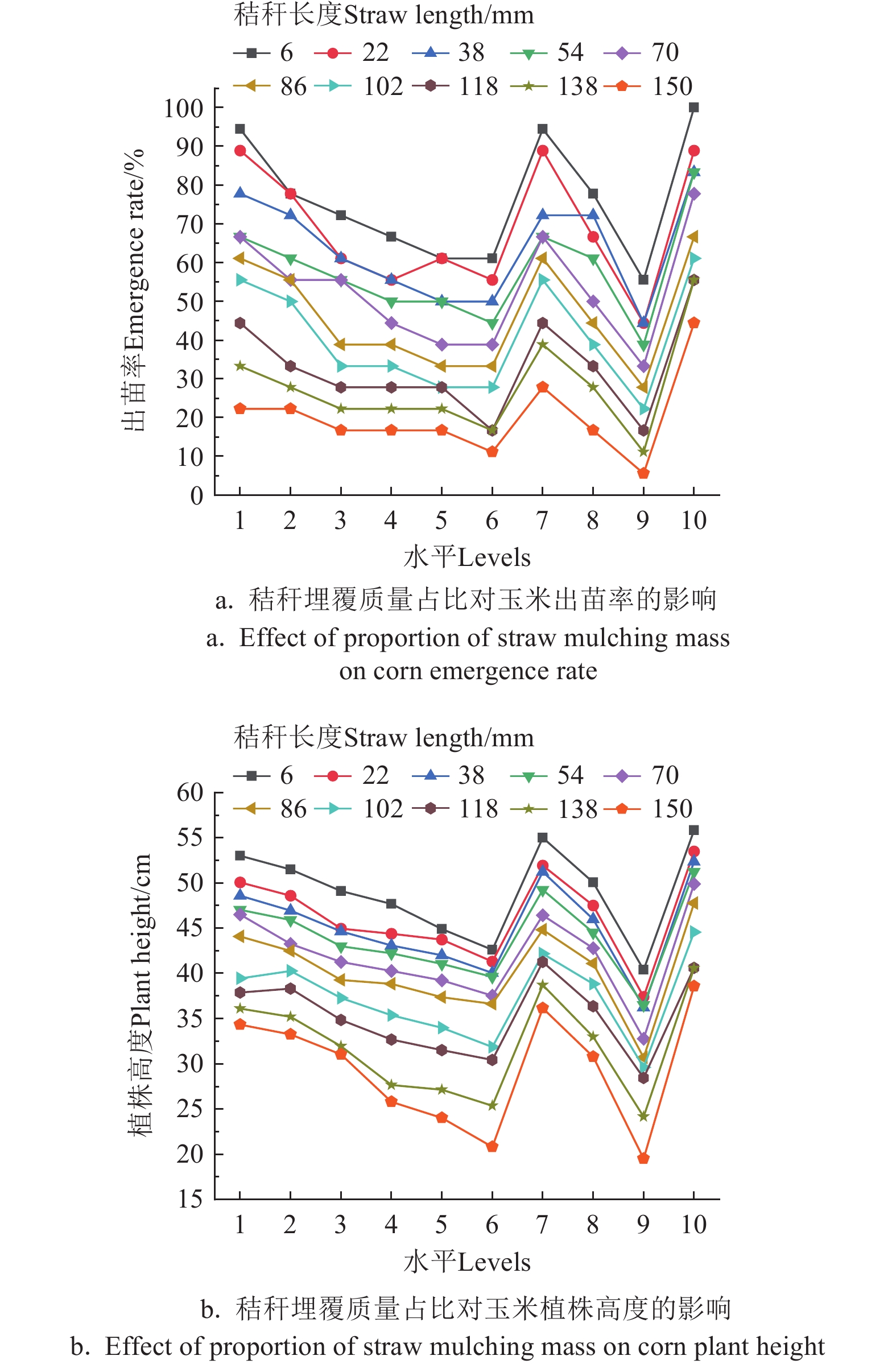

Straw length/ mm不同深度土层秸秆埋覆质量占比

Proportion of straw mulching mass in different soil depths≥0~5 cm ≥5~10 cm ≥10~15 cm 1 6 1/6 2/6 3/6 2 22 1/6 3/6 2/6 3 38 2/6 1/6 3/6 4 54 2/6 3/6 1/6 5 70 3/6 1/6 2/6 6 86 3/6 2/6 1/6 7 102 1/6 1/6 4/6 8 118 1/6 4/6 1/6 9 134 4/6 1/6 1/6 10 150 2/6 2/6 2/6 采用单因素试验方法,共进行100组试验,每组试验重复3次,总计300次。试验步骤如图1所示。首先对油菜秸秆进行切割收集,按照表1剪切成对应的长度,然后按照不同质量占比与土壤进行混合,混合均匀后埋至对应的土层深度,进行播种,在1个月后测量出苗率与植株高度。例如,要进行秸秆长度为1水平、不同深度土层秸秆埋覆质量占比为1水平的试验,首先将秸秆剪切为6 mm,然后将试验田块(1 m×1 m)的≥0~5 cm土壤取出与200 g秸秆在容器1中均匀混合,继而将试验田块的≥5~10 cm土壤取出与400 g秸秆在容器2中均匀混合,最后将试验田块的≥10~15 cm土壤取出与600 g秸秆在容器3中均匀混合,最后将3个容器中的秸秆-土壤混合体按照取土时的土壤深度回填至试验田块,再进行玉米播种。

1.3 测定指标与方法

1.3.1 出苗率

在播种1个月后测量每个试验组玉米种子的出苗数量,并根据式(1)算出苗率。

$$ \eta = \frac{{{N_1}}}{{{N_0}}} \times 100\text{%} $$ (1) 式中η为出苗率,%;N0为每组试验田块玉米播种数量;N1为出苗数量。

1.3.2 玉米植株高度

播种1个月后,对每个试验组田块的所有玉米植株的高度进行测量,剔除最大值和最小值,按照式(2)取平均值作为该组玉米植株高度。

$$ h = \sum\limits_{i = 1}^N {{h_i}} /N $$ (2) 式中h为玉米植株高度,cm;hi为每个试验组田块有效数据的第i株玉米的植株高度,cm;N为每个试验组田块内剔除高度最大和最小值的玉米株数。

1.3.3 秸秆埋覆质量变异系数

采用秸秆埋覆质量变异系数评价秸秆埋覆均匀性,根据每组试验≥0~5、≥5~10和≥10~15 cm土层的秸秆埋覆质量,按照式(3)计算秸秆埋覆质量变异系数。

$$ {c_v} = \frac{{\sqrt {\dfrac{1}{{n - 1}}\displaystyle\sum\limits_{i = 1}^n {{{({m_i} - \overline m )}^2}} } }}{{\overline m }} \times 100\text{%} $$ (3) 式中cv表示秸秆埋覆质量变异系数,%;mi为从上至下第i层土壤中的秸秆质量,g;$ \overline m $为秸秆埋覆质量平均值,$ \overline m = \dfrac{1}{n}\displaystyle\sum\limits_{i = 1}^n {{m_i}} $,g;n为土壤分层层数,n=3。

2. 结果与分析

播种1个月后对玉米出苗数量和植株高度进行测量统计,每组试验重复3次,以3次测量平均值作为该组试验结果。

2.1 油菜秸秆长度对玉米出苗率和植株高度的影响

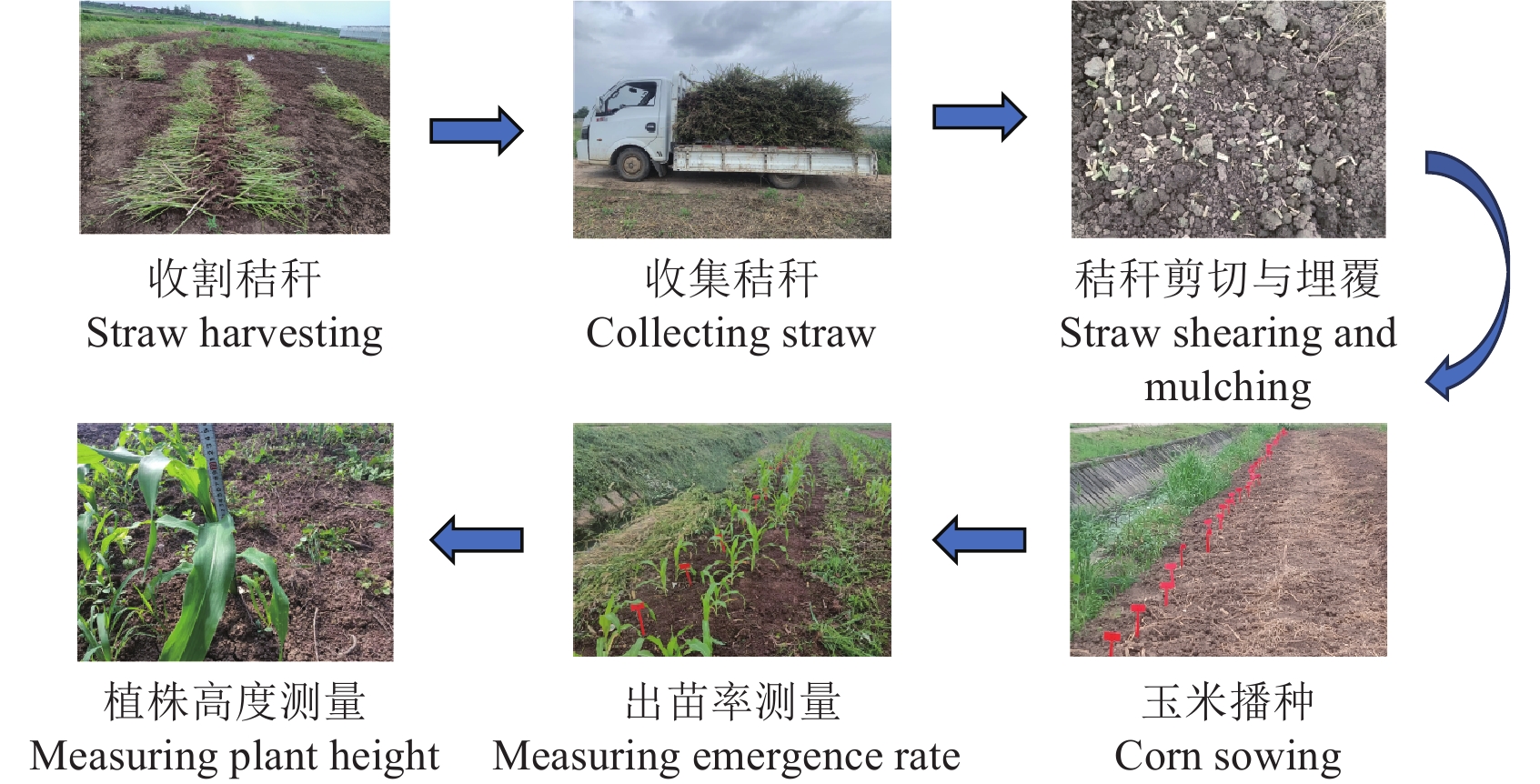

试验得到的不同秸秆埋覆质量占比下出苗率和植株高度同秸秆粉碎长度的关系如图2所示。

![]() 图 2 出苗率和植株高度与秸秆粉碎长度的关系注: x表示秸秆长度;η表示出苗率;h表示植株高度; 1~10表示表1中不同深度土层秸秆埋覆质量占比的10个水平。下同。Figure 2. Relationship between emergence rate, plant height and straw lengthNote: x means straw length; η means emergence rate; h means plant height; the No. of 1 to 10 means the 10 levels the proportion of straw mass in different depths of soil layers in Table 1. The same below.

图 2 出苗率和植株高度与秸秆粉碎长度的关系注: x表示秸秆长度;η表示出苗率;h表示植株高度; 1~10表示表1中不同深度土层秸秆埋覆质量占比的10个水平。下同。Figure 2. Relationship between emergence rate, plant height and straw lengthNote: x means straw length; η means emergence rate; h means plant height; the No. of 1 to 10 means the 10 levels the proportion of straw mass in different depths of soil layers in Table 1. The same below.由图2a可知,玉米出苗率和油菜秸秆长度成线性关系,不同秆埋覆质量占比条件下,出苗率与秸秆长度拟合直线的决定系数在0.964~1.000之间,拟合度高,拟合直线斜率在−0.471~−0.324,各拟合直线近似平行,表明秸秆长度越短,越有利于促进种子萌发。经计算,秸秆长度每降低1 cm,出苗率提高3.83个百分点。不同深度土层秸秆埋覆质量占比取10水平即各层土壤中秸秆埋覆质量占比相同(秸秆埋覆质量变异系数为0)时玉米出苗率最高,达到100%。

由图2b可知,玉米植株高度和油菜秸秆长度成线性关系,不同秸秆埋覆质量占比条件下,植株高度与秸秆长度拟合直线决定系数在0.911~0.993之间,拟合直线斜率在−0.147~−0.121,各拟合直线近似平行,表明秸秆长度越短,越有利于促进作物生长,经计算,秸秆长度每降低1 cm,植株高度提高1.32 cm。不同深度土层埋覆秸秆质量占比取10水平时,即≥0~5、≥5~10和≥10~15 cm 土层中秸秆埋覆质量占比均相同(秸秆质量变异系数为0)时玉米株高度最大,达到55.84 cm。

综上可知,秸秆长度与秸秆埋覆质量占比对出苗率与植株高度具有相似的影响规律,秸秆粉碎长度越短、完全均匀埋覆对玉米播种质量影响最小。这是由于秸秆粉碎长度越短,与土壤混合越均匀,对土壤体积、容重、间隙等的影响越小,越能减少跑墒、漏风和种子架空等问题,有利于促进种子萌发与生长。

2.2 不同深度土层秸秆质量占比对玉米出苗率和植株高度的影响

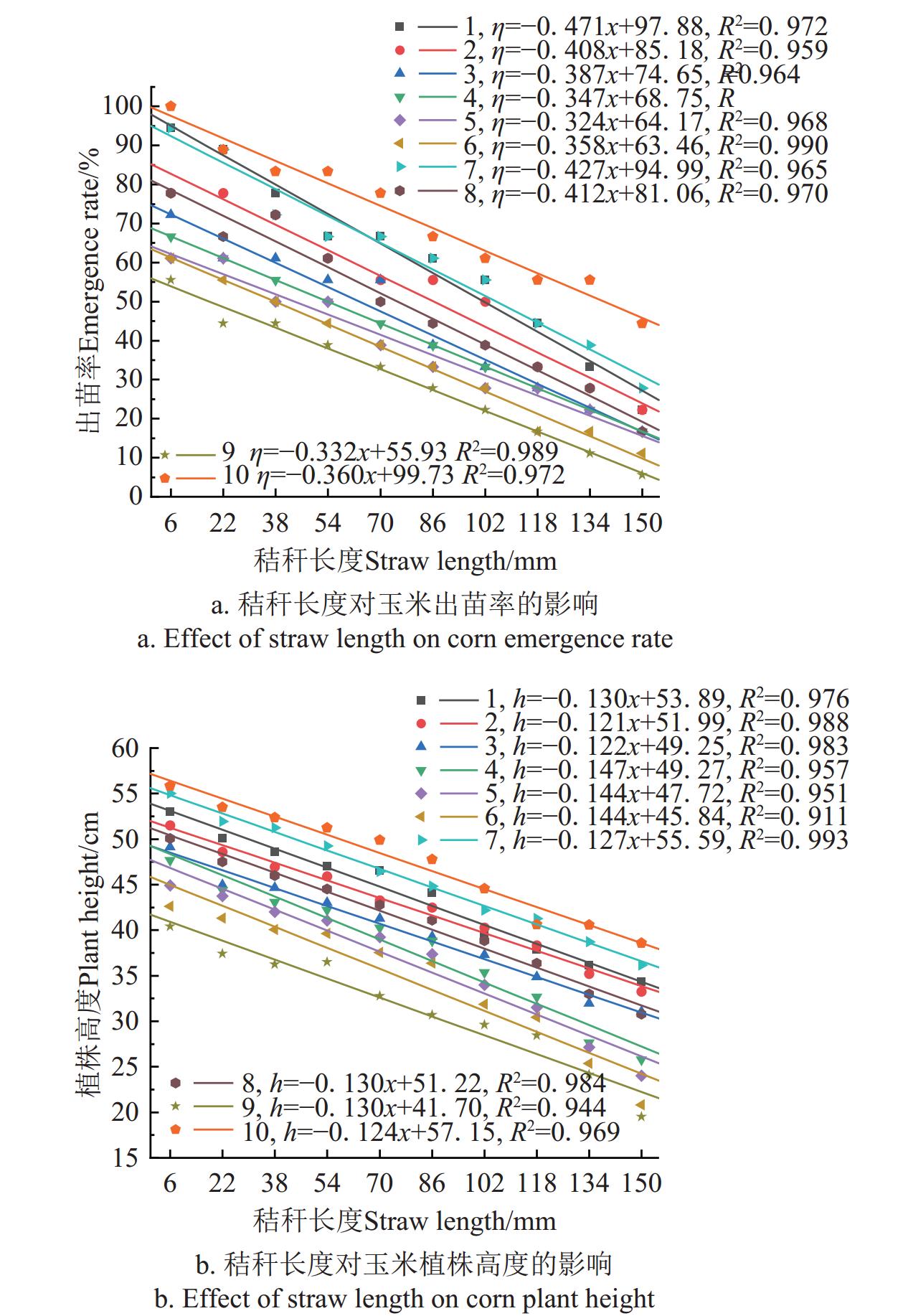

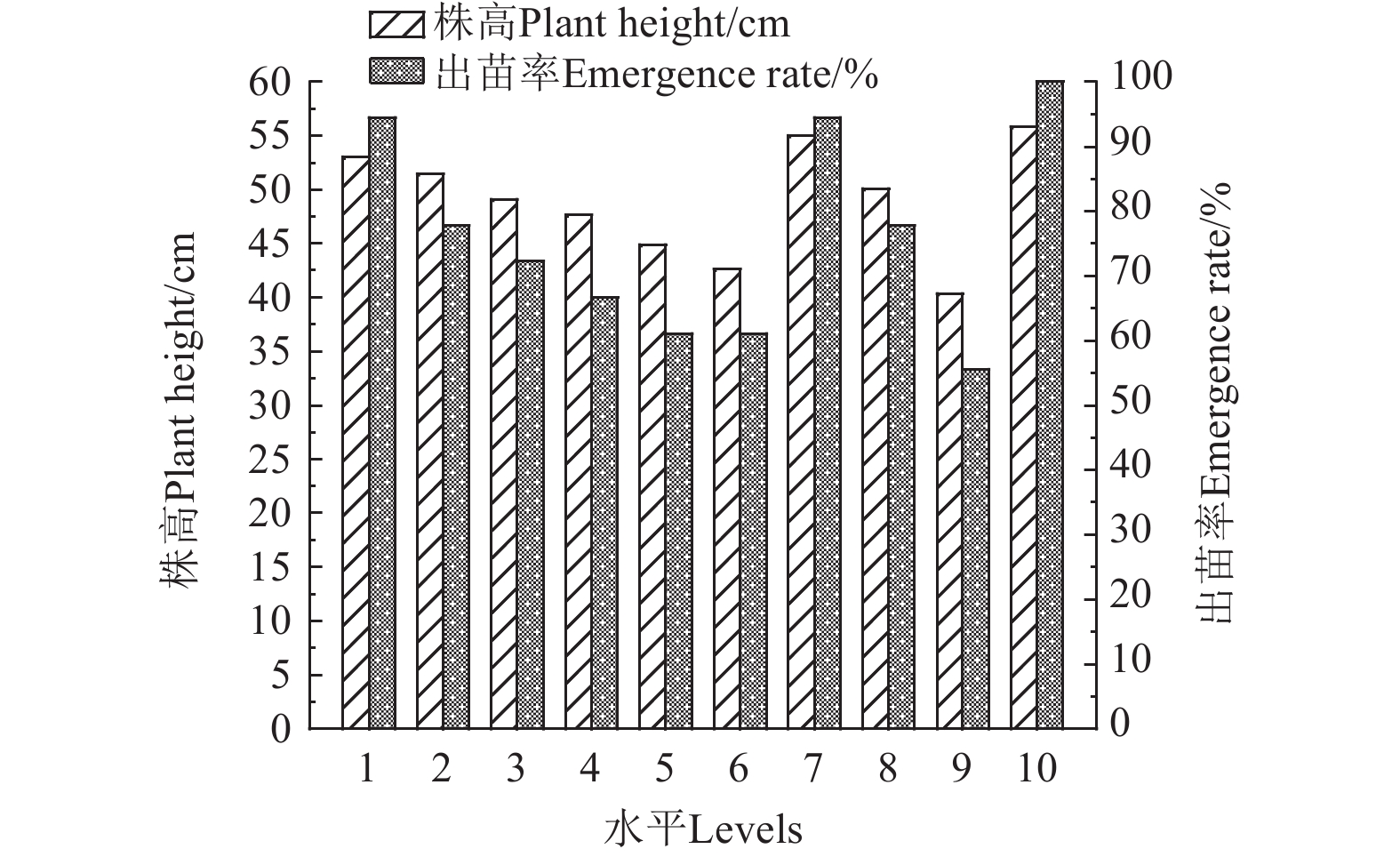

试验得到不同秸秆长度下玉米出苗率和植株高度在不同深度土层秸秆质量占比关系如图3所示。由图3a和图3b可知,不同秸秆长度下,出苗率与植株高度随不同深度土层秸秆质量占比变化的变化趋势呈现相似的变化规律,即不同深度土层秸秆质量占比对玉米出苗率与植株高度影响规律是相同的。

为便于分析这一变化规律,取玉米出苗率和植株高度最大时,即秸秆长度为6 mm时的玉米出苗率和植株高度与不同深度土层秸秆埋覆质量占比的关系,如图4。

分析表1和图4可知,不同深度土层秸秆埋覆质量占比在1~6水平时,出苗率和植株高度呈下降趋势,在7~9水平呈另一个下降趋势,在10水平取得最大值。而秸秆埋覆质量占比在1~6水平时,秸秆埋覆质量变异系数相同,为50%。秸秆埋覆质量占比在7~9水平时,秸秆埋覆质量变异系数为86.6%。在不同深度土层秸秆埋覆质量变异系数一定时(秸秆埋覆均匀度相同),出苗率和植株高度随秸秆埋覆质量占的变化趋势与≥0~5 cm土层的变化趋势相反。例如1~6水平时的出苗率与植株高度从大到小依次为:水平1和水平2,水平3和水平4,水平5和水平6。水平7~9水平时对应的出苗率与植株高度,水平7大于水平9。可见,秸秆埋覆均匀度相同时,出苗率与植株高度由≥0~5 cm土层秸秆埋覆质量占比决定,降低上层土壤秸秆埋覆质量占比有助于促进种子萌发与作物生长。

埋覆均匀度相同(1~6、7~9和10水平,对应的秸秆埋覆质量变异系数分别为50%、86.6%、0)条件下,当≥0~5 cm深度土层秸秆埋覆质量占比相同(水平1和2、水平3和4、水平5和6,水平7和8)时,≥5~10 cm深度土层秸秆埋覆质量占比越小,出苗率与植株高度越大。例如水平1与水平2在≥0~5 cm深度土层秸秆埋覆质量占比相同(1/6),但对应的出苗率与株高为水平1(≥5~10 cm土层秸秆埋覆质量占2/6)大于水平2(≥5~10 cm土层秸秆埋覆质量占3/6),水平3和水平4,水平5和水平6,水平7和水平8亦然。可见,≥0~5 cm深度土层秸秆埋覆质量占比相同时,出苗率与植株高度由≥5~10 cm的土层秸秆埋覆质量占比决定,降低中上层土壤的秸秆埋覆质量,提高底层土壤秸秆埋覆质量,实现秸秆深埋,有助于构建良好的种床与苗床。

在秸秆均匀埋覆情况下(即不同深度土层秸秆埋覆质量变异系数为0),出苗率与植株高度最大,但这一理想值在实际秸秆还田作业中是难以实现的,因为秸秆在从地表运移到土壤中时位移不同,难以完全在土壤中均匀分布。对比水平7~9(秸秆埋覆质量变异系数均为86.6%)与1~6(秸秆埋覆质量变异系数均为50%),水平7~9的秸秆埋覆质量变异系数(86.6%)高于水平1~6(50%),但均匀性低(秸秆埋覆质量变异系数高)的水平7的出苗率与植株高度却优于均匀性高(秸秆埋覆质量变异系数低)的水平1~6,因此单纯追求秸秆混埋均匀度未必能提高秸秆还田质量。

2.3 秸秆还田质量评价与提升方法

目前主要采用覆盖率(秸秆覆盖地表的秸秆个数占比)和埋覆率(埋入土壤中的秸秆质量占比)等指标评价秸秆还田质量[25]。如,何瑞银等[26]采用网格划分法,将土壤划分为细小立体网格,统计网格内的秸秆质量,计算秸秆质量变异系数,评价秸秆埋覆的均匀程度。ZHOU等[27]采用秸秆在土壤不同深度中的质量分布描述还田秸秆在土壤中的空间分布状态。从试验结果看,秸秆质量空间分布均匀性对播种质量具有显著影响,但并非埋覆越均匀播种质量越好。上层秸秆埋覆量相较于埋覆均匀性与播种质量具有更加紧密的关联性,适宜作为秸秆还田质量评价标准。还田秸秆长度对秸秆还田质量具有显著影响,目前的秸秆粉碎国标要求给出了长度上限,即玉米、高粱、油菜等粗壮秸秆不超过100 mm,水稻、小麦等绵密秸秆不超过150 mm[28],采用秸秆长度分布或秸秆长度平均值更能准确衡量秸秆粉碎程度,有利于精确评价秸秆还田质量。

基于试验分析,可以从降低秸秆粉碎长度和上层土壤秸秆埋覆量两个方面提高秸秆还田质量。从降低秸秆粉碎长度方面,可采用多级粉碎[29]、捡拾粉碎[30]、制粒[31]、碳化焚烧[32]等方式提高秸秆粉碎程度,甚至度达到粉末化水平。从降低上层土壤秸秆埋覆量方面,可采用犁翻[33]、整秆还田[34]、沟埋[35]等,或采用双轴旋耕[36]、人字型旋埋刀辊[37]、双螺旋对置埋覆辊[38]等埋覆装置实现秸秆均匀混埋,提高中下层土壤秸秆含量。还可以采用捡拾-粉碎-沟埋[39],粉碎-旋耕-埋覆[24]等复合工艺,降低秸秆粉碎长度,提高秸秆埋覆深度。

3. 结 论

本文通过2因素10水平单因素试验,阐明了油菜秸秆还田长度(6~150 mm)及秸秆在不同深度土层(0~15 cm)的埋覆量对玉米出苗率与植株高度的影响,提出秸秆还田质量评价与提升方法,主要结论如下:

1)不同深度土层秸秆埋覆质量占比相同时,玉米出苗率和植株高度随着油菜秸秆长度增大而减小,且呈线性关系,秸秆长度每降低1 cm,出苗率增加3.83个百分点,植株高度增加1.32 cm,降低秸秆粉碎长度有利于促进种子萌发与生长;

2)当秸秆粉碎长度为6 mm ,且秸秆埋覆均匀时,玉米出苗率和植株高度最大,达到100%和55.84 cm;

3)油菜秸秆长度相同、但埋覆不均匀时(秸秆埋覆质量变异系数不为0),玉米出苗率和植株高度由上层土壤(≥0~5 cm)秸秆埋覆质量占比决定,上层土壤秸秆埋覆质量占比越低,玉米出苗率和植株高度越高;当上层土壤(≥0~5 cm)秸秆埋覆质量占比相同时,玉米出苗率和植株高度由中层土壤(≥5~10 cm)秸秆埋覆质量占比决定,中层土壤秸秆埋覆质量占比越低,玉米出苗率和植株高度越高;单一提升秸秆均匀性,不一定能够实现种床质量提升,降低上层秸秆埋覆质量,提高底层土壤(≥10~15 cm)秸秆埋覆质量占比,实现秸秆深埋,是提高秸秆还田质量的关键。

-

图 2 出苗率和植株高度与秸秆粉碎长度的关系

注: x表示秸秆长度;η表示出苗率;h表示植株高度; 1~10表示表1中不同深度土层秸秆埋覆质量占比的10个水平。下同。

Figure 2. Relationship between emergence rate, plant height and straw length

Note: x means straw length; η means emergence rate; h means plant height; the No. of 1 to 10 means the 10 levels the proportion of straw mass in different depths of soil layers in Table 1. The same below.

表 1 试验因素与水平

Table 1 Experimental factors and levels

水平Level 秸秆长度

Straw length/ mm不同深度土层秸秆埋覆质量占比

Proportion of straw mulching mass in different soil depths≥0~5 cm ≥5~10 cm ≥10~15 cm 1 6 1/6 2/6 3/6 2 22 1/6 3/6 2/6 3 38 2/6 1/6 3/6 4 54 2/6 3/6 1/6 5 70 3/6 1/6 2/6 6 86 3/6 2/6 1/6 7 102 1/6 1/6 4/6 8 118 1/6 4/6 1/6 9 134 4/6 1/6 1/6 10 150 2/6 2/6 2/6 -

[1] 中华人民共和国国家统计局. 中国统计年鉴[M]. 北京:中 国统计出版社,2023. [2] 严东权,薛颖昊,徐志宇,等. 我国农作物秸秆直接还田利用现状、技术模式及发展建议[J]. 中国农业资源与区划,2023,44(4):1-14. YAN Dongquan, XUE Yinghao, XU Zhiyu, et al. Current utilization status, technical models and development proposals for direct crop straw returning to field in China[J]. Chinese Journal of Agricultural Resources and Regional Planning, 2023, 44(4): 1-14. (in Chinese with English abstract)

[3] 孙春梅,董玉兵,纪力,等. 生物质发电厂草木灰农业利用技术[J]. 大麦与谷类科学,2022,39(6):60-66,70. SUN Chunmei, DONG Yubing, JI Li, et al. Technology of agricultural utilization of plant ash, the waste of biomass power plants[J]. Barley and Cereal Sciences, 2022, 39(6): 60-66,70. (in Chinese with English abstract)

[4] 贺继奎,程勇,何泽威,等. 油菜对超高密度直播的响应与产量构成性状分析[J]. 中国油料作物学报,2024,46(2):334-340. HE Jikui, CHENG Yong, HE Zewei, et al. Response and yield components of 54 varieties to high seeding rate planting in rapeseed(Brassica napus L. )[J]. Chinese Journal of Oil Crop Sciences, 2024, 46(2): 334-340. (in Chinese with English abstract)

[5] TIAN C, ZHOU X, LIU Q, et al. Increasing yield, quality and profitability of winter oilseed rape (Brassica napus L.) under combinations of nutrient levels in fertilizer and planting density[J]. Crop & Pasture Science, 2020, 71(12): 1010-1019.

[6] 万星宇,舒彩霞,廖庆喜,等. 高地隙履带自走式中间条铺油菜割晒机设计与试验[J]. 农业机械学报,2022,53(9):109-121. DOI: 10.6041/j.issn.1000-1298.2022.09.011 WAN Xingyu, SHU Caixia, LIAO Qingxi, et al. Designand experiment of self-propelled middle-placement rape windrower with high ground clearance crawler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(9): 109-121. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2022.09.011

[7] 刘淑军,李冬初,黄晶,等. 1988-2018年中国水稻秸秆资源时空分布特征及还田替代化肥潜力[J]. 农业工程学报,2021,37(11):151-161. DOI: 10.11975/j.issn.1002-6819.2021.11.017 LIU Shujun, LI Dongchu, HUANG Jing et al. Temporal and spatial distribution characteristics of rice stalk resources and its potential of synthetic fertilizers substitution returning to farmland in China from 1988 to 2018[J]. Transactions of the ChineseSociety of Agricultural Engineering (Transactions of the CSAE), 2021, 37(11): 151-161. (in Chinese with English abstract) DOI: 10.11975/j.issn.1002-6819.2021.11.017

[8] 丛宏斌,姚宗路,赵立欣,等. 中国农作物秸秆资源分布及其产业体系与利用路径[J]. 农业工程学报,2019,35(22):132-140. DOI: 10.11975/j.issn.1002-6819.2019.22.015 CONG Hongbin, YAO Zonglu, ZHAO Lixin, et al. Distribution of crop straw resources and its industrial system and utilization path in China[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2019, 35(22): 132-140. (in Chinese with English abstract) DOI: 10.11975/j.issn.1002-6819.2019.22.015

[9] 李福建. 机械耕播方式对稻茬小麦幼苗质量与产量形成的 影响机理及其调控[D]. 扬州,扬州大学,2022. LI Fujian. Mechanism and Regulation of Mechanized Tillage and Sowing Methods Effecting on Seedling Quality and Grain Yield Formation of Wheat in Rice Stubble[D]. Yangzhou: Yangzhou University, 2022. (in Chinese with English abstract)

[10] 章力干,石心怡,王玉宝,等. 秸秆还田对中国主要粮食作物病害影响的Meta分析[J]. 农业工程学报,2022,38(21):93-100. DOI: 10.11975/j.issn.1002-6819.2022.21.012 ZHANG Ligan, SHI Xinyi, WANG Yubao, et al. Meta-analysis for the impacts of straw return on the diseases of major grain crops in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(21): 93-100. (in Chinese with English abstract) DOI: 10.11975/j.issn.1002-6819.2022.21.012

[11] LI Z K, SHEN Y, ZHANG W Y, et al. Effects of long-term straw returning on rice yield and soil properties and bacterial community in a rice-wheat rotation system[J]. Field Crops Research, 2022, 291: 108800.

[12] 阳绪英. 三种模式下油菜秸秆腐烂分解速度分析[J]. 南方农业,2014,8(22):40-41. DOI: 10.3969/j.issn.1673-890X.2014.08.016 [13] 庞荔丹. 玉米秸秆还田腐解率及其对土壤养分影响[D]. 哈尔滨:东北农业大学,2017. PANG Lidan. Decomposition Rate of Corn Stra Returning and Its Effects on Soil Nutrients[D]. Harbin: Northeast Agricultural University, 2017. (in Chinese with English abstract)

[14] 徐高明,丁启朔,汪小旵,等. 秸秆-土壤-旋耕机交互下秸秆位移与埋覆效果研究[J]. 农业机械学报,2022,53(7):23-29. DOI: 10.6041/j.issn.1000-1298.2022.07.002 XU Gaoming, DING Qishuo, WANG Xiaochan, et al. Analysis of straw displacement and burying effect in straw-soil-rotary tiller interaction[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(7): 23-29. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2022.07.002

[15] 胡宏祥,程燕,马友华,等. 油菜秸秆还田腐解变化特征及其培肥土壤的作用[J]. 中国生态农业学报,2012,20(3):297-302. DOI: 10.3724/SP.J.1011.2012.00297 HU Hongxiang, CHENG Yan, MA Youhua, et al. Decomposition characteristics of returned rapeseed straw in soil and effects on soil fertility[J]. Chinese Journal of Eco-Agriculture, 2012, 20(3): 297-302. (in Chinese with English abstract) DOI: 10.3724/SP.J.1011.2012.00297

[16] KONG F X, JIU A M, LI F M, et al. Deep tillage combined with straw bio char return increases rice yield by improving nitrogen availability and root distribution in the subsoil[J]. Field Crops Research, 2024, 315: 109481. DOI: 10.1016/j.fcr.2024.109481

[17] LIU N, LI Y Y, CONG P, et al. Depth of straw incorporation significantly alters crop yield, soil organic carbon and total nitrogen in the North China Plain[J]. Soil & Tillage Research, 2021, 205: 104772.

[18] 秦宽,曹成茂,廖移山,等. 秸秆还田施肥点播机粉碎抛撒装置结构设计与优化[J]. 农业工程学报,2020,36(3):1-10. QIN Kuan, CAO Chengmao, LIAO Yishan, et al. Design and optimization of crushing and throwing device for straw returning to field and fertilizing hill-seeding machine[J]. Transactions of the ChineseSociety of Agricultural Engineering (Transactions of the CSAE), 2020, 36(3): 1-10. (in Chinese with English abstract)

[19] 田仲和,高善民,朱恩,等. 麦秸还田不均匀对直播水稻生长的影响及对策[J]. 土壤肥料,2002(1):26-29. TIAN Zhonghe, GAO Shanmin, ZHU En, et al. Effect of non uniform returning of wheat straw to field on growth of direct sown rice and countermeasures concerned[J]. Soil and Fertilizer Sciences in China, 2002(1): 26-29. (in Chinese with English abstract)

[20] 顾峰玮,胡志超,陈有庆,等. “洁区播种”思路下麦茬全秸秆覆盖地花生免耕播种机研制[J]. 农业工程学报,2016,32(20):15-23. DOI: 10.11975/j.issn.1002-6819.2016.20.002 GU Fengwei, HU Zhichao, CHEN Youqing, et al. Development and experiment of peanut no-till planter under full wheat straw mulching based on “clean area planting”[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 15-23. (in Chinese with English abstract) DOI: 10.11975/j.issn.1002-6819.2016.20.002

[21] 李超,程凯凯,廖育林,等. 秸秆深度粉碎均匀抛洒还田降低秸秆焚烧率并提高养分归还量[J]. 植物营养与肥料学报,2021,27(7):1141-1150. DOI: 10.11674/zwyf.2021088 LI Chao, CHENG Kaikai, LIAO Yulin, et al. Deep smashing and uniform incorporation of straw prevent straw burning and improve the return of nutrients to soil[J]. Journal of Plant Nutrition and Fertilizers, 2021, 27(7): 1141-1150. (in Chinese with English abstract) DOI: 10.11674/zwyf.2021088

[22] 范围,吴景贵,李建明,等. 秸秆均匀还田对东北地区黑钙土土壤理化性质及玉米产量的影响[J]. 土壤学报,2018,55(4):835-846. DOI: 10.11766/trxb201709260363 FAN Wei, WU Jinggui, LI Jianming, et al. Effects of straw return on soil shysico-chemical properties of chernozem in Northeast China and Maize Yield Therein[J]. Acta Pedologica Sinica, 2018, 55(4): 835-846. (in Chinese with English abstract) DOI: 10.11766/trxb201709260363

[23] HUANG W, WU J F, PAN X H, et al. Effects of long-term straw return on soil organic carbon fractions and enzyme activities in a double-cropped rice paddy in South China[J]. Journal of Integrative Agriculture, 2021, 20(1): 236-247.

[24] 邓玮鸿. 油菜秸秆粉碎旋耕埋覆还田机设计与试验[D]. 武汉:华中农业大学,2023. DENG Weihong. Design and Experiment of Rapeseed Straw Crush Rotary Tillage and Burial Returning Machine [D]. Wuhan:Agricultural University, 2023. (in Chinese with English abstract)

[25] LIANG F, WANG Y B , DENG W H, et al. Research status and development trend of mechanized straw returning technology. A review [J]. INMATEH-Agricultural Engineering, 2021, 65(3): 465-475.

[26] 何瑞银,段庆飞,陈信信,等. 旋耕还田秸秆空间分布质量离散元分析[J]. 农业机械学报,2022,53(6):44-53. DOI: 10.6041/j.issn.1000-1298.2022.06.004 HE Ruiyin, DUAN Qingfei, CHEN Xinxin, et al. DEM analysis of spatial distribution quality of rotary tillage straw returning[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(6): 44-53. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2022.06.004

[27] ZHOU H, ZHANG C L, ZHANG W L, et al. Evaluation of straw spatial distribution after straw incorporation into soil for different tillage tools[J]. Soil & Tillage Research, 2020, 196: 104440.

[28] 中国机械工业联合会. GB/T 24675.6-2021保护性耕作机械 第6部分:秸秆粉碎还田机[S]. 北京:中国标准出版社,2021. [29] 王将,王晓燕,李洪文,等. 水稻秸秆激荡滑切与撕裂两级切割粉碎装置设计与试验[J]. 农业机械学报,2021,52(10):28-40. DOI: 10.6041/j.issn.1000-1298.2021.10.003 WANG Jiang, WANG Xiaoyan, LI Hongwen, et al. Design and experiment of rice straw chopping device for agitation sliding cutting and tearing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10): 28-40. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2021.10.003

[30] 邱进,吴明亮,官春云,等. 动定刀同轴水稻秸秆切碎还田装置结构设计与试验[J]. 农业工程学报,2015,31(10):11-19. DOI: 10.11975/j.issn.1002-6819.2015.10.002 QIU Jin, WU Mingliang, GUAN Chunyun, et al. Design and experiment of chopping device with dynamic fixed knife coaxial for rice straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(10): 11-19. (in Chinese with English abstract) DOI: 10.11975/j.issn.1002-6819.2015.10.002

[31] 王伟,宫元娟,白雪卫,等. 移动式秸秆制粒机作业速度调控系统研究[J]. 农业机械学报,2021,52(10):186-195. DOI: 10.6041/j.issn.1000-1298.2021.10.019 WANG Wei, GONG Yuanjuan, BAI Xuewei, et al. Investigation on operating speed regulation system of mobile straw granulator[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10): 186-195. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2021.10.019

[32] 赵立欣,田利伟,贾吉秀,等. 移动式玉米秸秆热解炭化原位还田设备研究[J]. 农业机械学报,2023,54(1):357-363. DOI: 10.6041/j.issn.1000-1298.2023.01.036 ZHAO Lixin, TIAN Liwei, JIA Jixiu, et al. Mobile equipment study of corn stalk in-situ returning carbonization[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(1): 357-363. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2023.01.036

[33] HEINZE S, RAUBER R, JOERGENSEN R G. Influence of mouldboard plough and rotary harrow tillage on microbial biomass and nutrient stocks in two long-term experiments on loess derived Luvisols[J]. Applied Soil Ecology, 2016, 6: 405-412.

[34] 王金峰,陈博闻,姜岩,等. 水稻秸秆全量深埋还田机设计与试验[J]. 农业机械学报,2020,51(1):84-93. WANG Jinfeng, CHEN Bowen, JIANG Yan, et al. Design and experiment on machine for rice straw full quantity deep buried into field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51 (1): 84-93. (in Chinese with English abstract)

[35] 陈桂斌,卢彩云,何进,等. 秸秆条带捡拾粉碎深埋装置设计与试验[J]. 农业机械学报,2021,52(10):16-27. DOI: 10.6041/j.issn.1000-1298.2021.10.002 CHEN Guibin, LU Caiyun, HE Jin, et al. Design and experiment of straw pickup-crushed and deep buried device under strip-tillage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10): 16-27. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2021.10.002

[36] 管春松,崔志超,高庆生,等. 双轴旋耕碎土试验台设计与分层耕作试验[J]. 农业工程学报,2021,37(10):28-37. DOI: 10.11975/j.issn.1002-6819.2021.10.004 GUAN Chunsong, CUI Zhichao, GAO Qingsheng, et al. Design of biaxial rotary tillage soil test bench and layered tillage test[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(10): 28-37. (in Chinese with English abstract) DOI: 10.11975/j.issn.1002-6819.2021.10.004

[37] 祝英豪,张居敏,曾荣,等. 人字型水旱两用旋埋刀辊设计与试验[J]. 农业机械学报,2019,50(4):49-57,273. DOI: 10.6041/j.issn.1000-1298.2019.04.006 ZHU Yinghao, ZHANG Jumin, ZENG Rong, et al. Design and experiment of herringbone type rotary blade roller for Burying stubble in paddy field and dry land[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(4): 49-57,273. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2019.04.006

[38] 梁方,邓玮鸿,罗历强,等. 油菜秸秆对置双螺旋埋覆还田装置设计与优化[J]. 农业工程学报,2023,39(21):12-20. LIANG Fang, DENG Weihong, LUO Liqiang, et al. Optimizing double-screw burying device for rape straw returning[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(21): 12-20. (in Chinese with English abstract)

[39] 仝振伟,李洪文,卢彩云,等. 直注式秸秆捡拾粉碎深埋机设计与试验[J]. 农业机械学报,2024,55(7):83-95. DOI: 10.6041/j.issn.1000-1298.2024.07.009 TONG Zhenwei, LI Hongwen, LU Caixia, et al. Design and experiment of direct-injection and crushing deep burying machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2024, 55(7): 83-95. (in Chinese with English abstract) DOI: 10.6041/j.issn.1000-1298.2024.07.009

下载:

下载:

下载:

下载: