Experimental investigation of performance and combustion characteristics in a direct injection hydrogen engine

-

摘要:

为探究缸内直喷氢发动机的性能和燃烧特性,该研究以四冲程氢发动机为研究对象,分析了氢发动机的性能以及点火定时对氢发动机燃烧特性和爆震的影响。保持节气门全开,同时选取怠速800 r/min到标定转速2 500 r/min各工况下的最佳点火定时进行试验。试验结果表明,在氢发动机的整个转速范围内,随着转速的增加氢发动机的扭矩先增大后减少,在1 500 r/min时发动机扭矩达到最大值。在整个外特性工况下,循环变动率最高仅为5.36 %,氢发动机稳定运转;随着点火定时的适当提前,燃烧持续期减小,放热率峰值增大,燃烧更加集中,使燃烧过程更接近定容燃烧,但缸内燃烧较为剧烈,燃烧循环变动增大;随着点火定时的提前,缸内未燃混合气的自燃倾向增大,平均爆震强度增大,发动机爆震倾向增大。研究结果可为缸内直喷发动机研发提供参考。

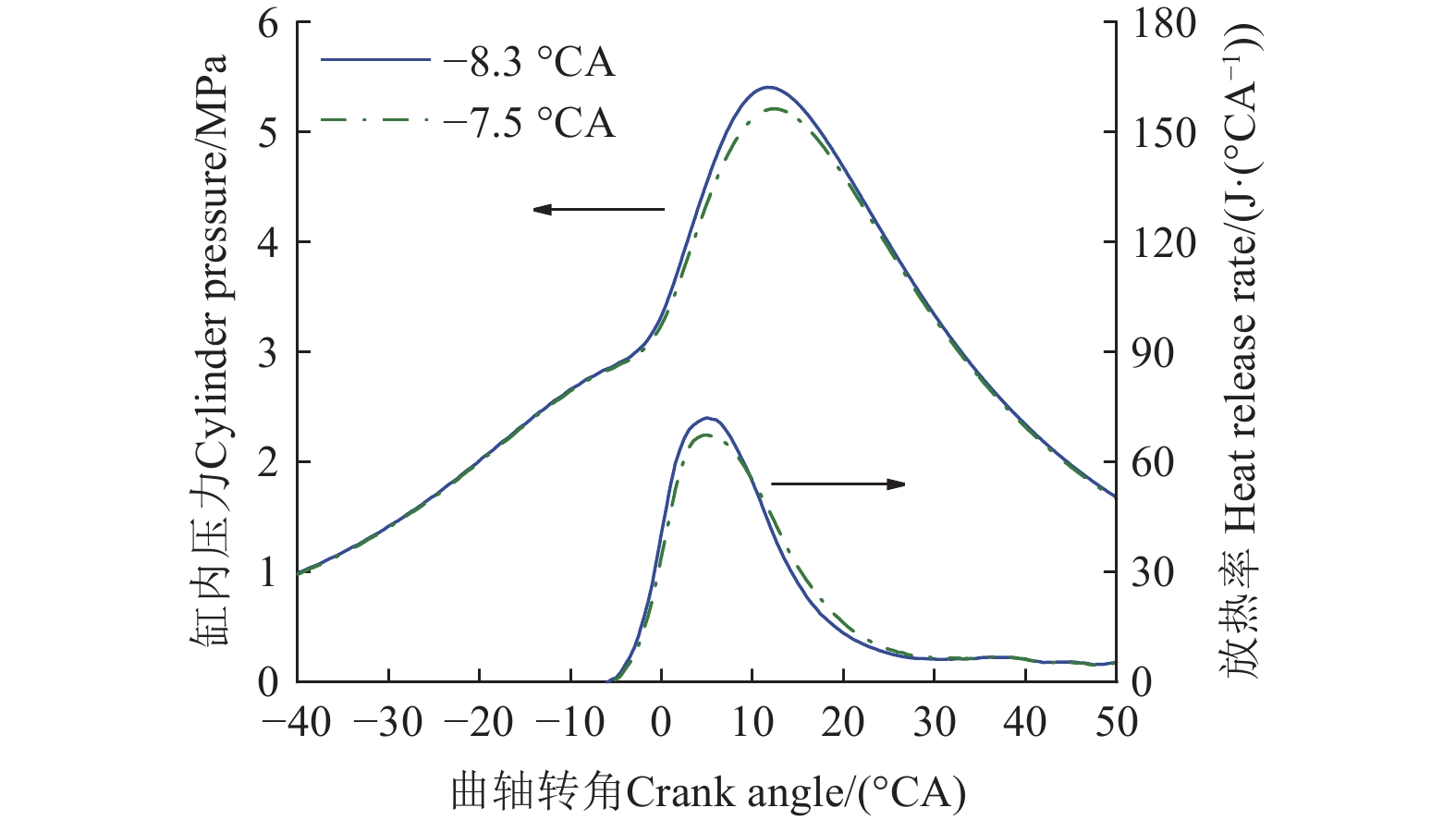

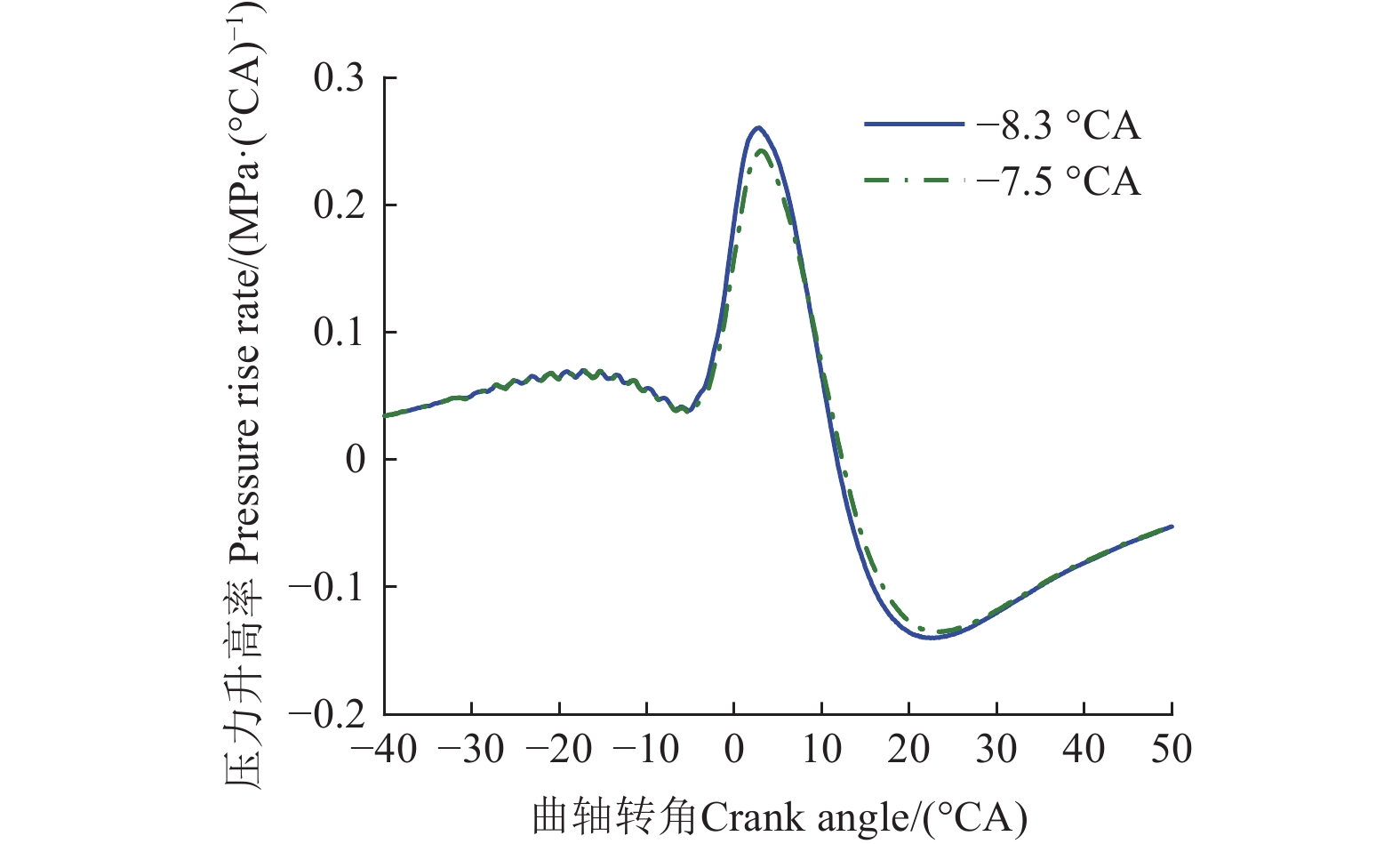

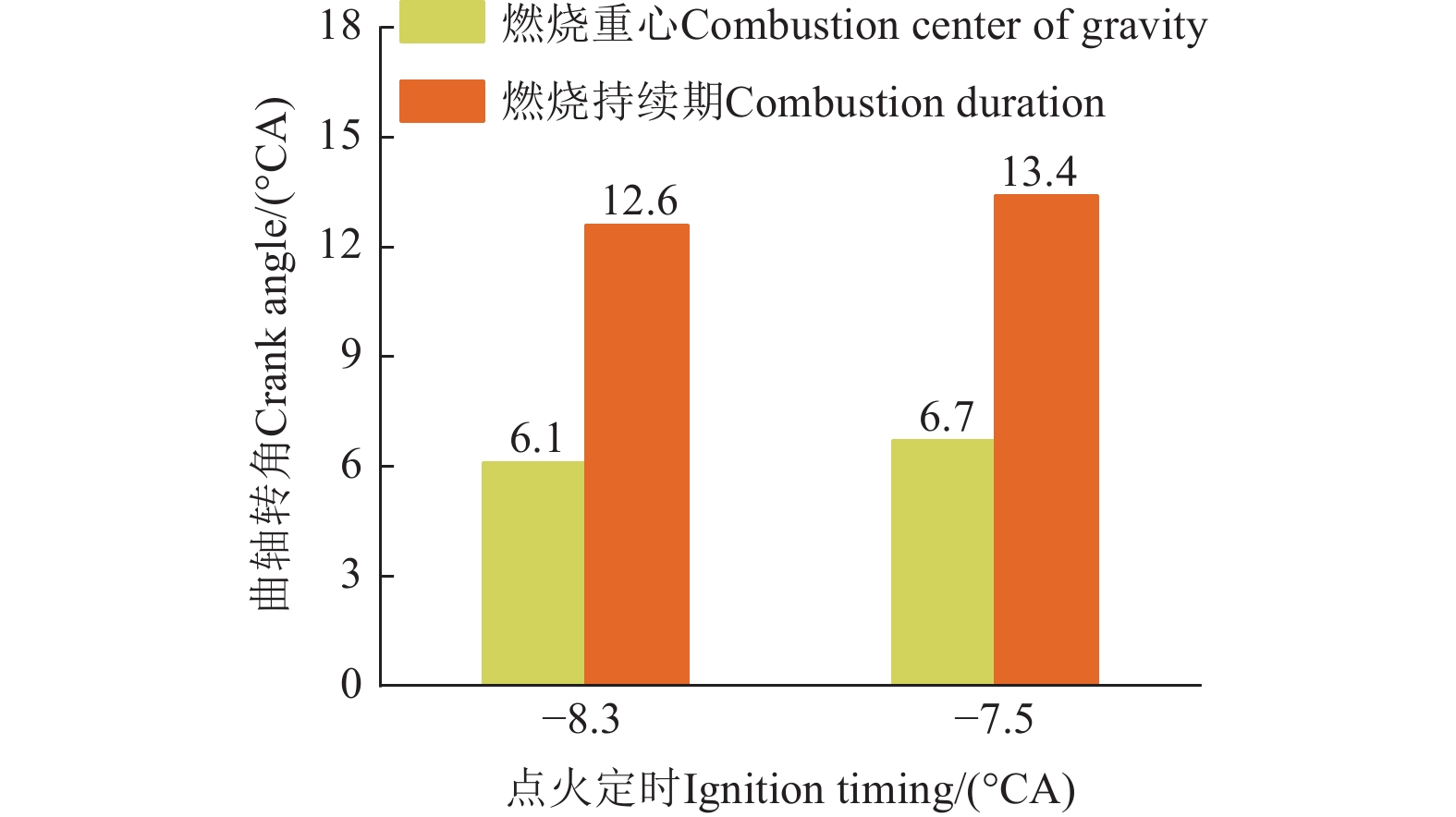

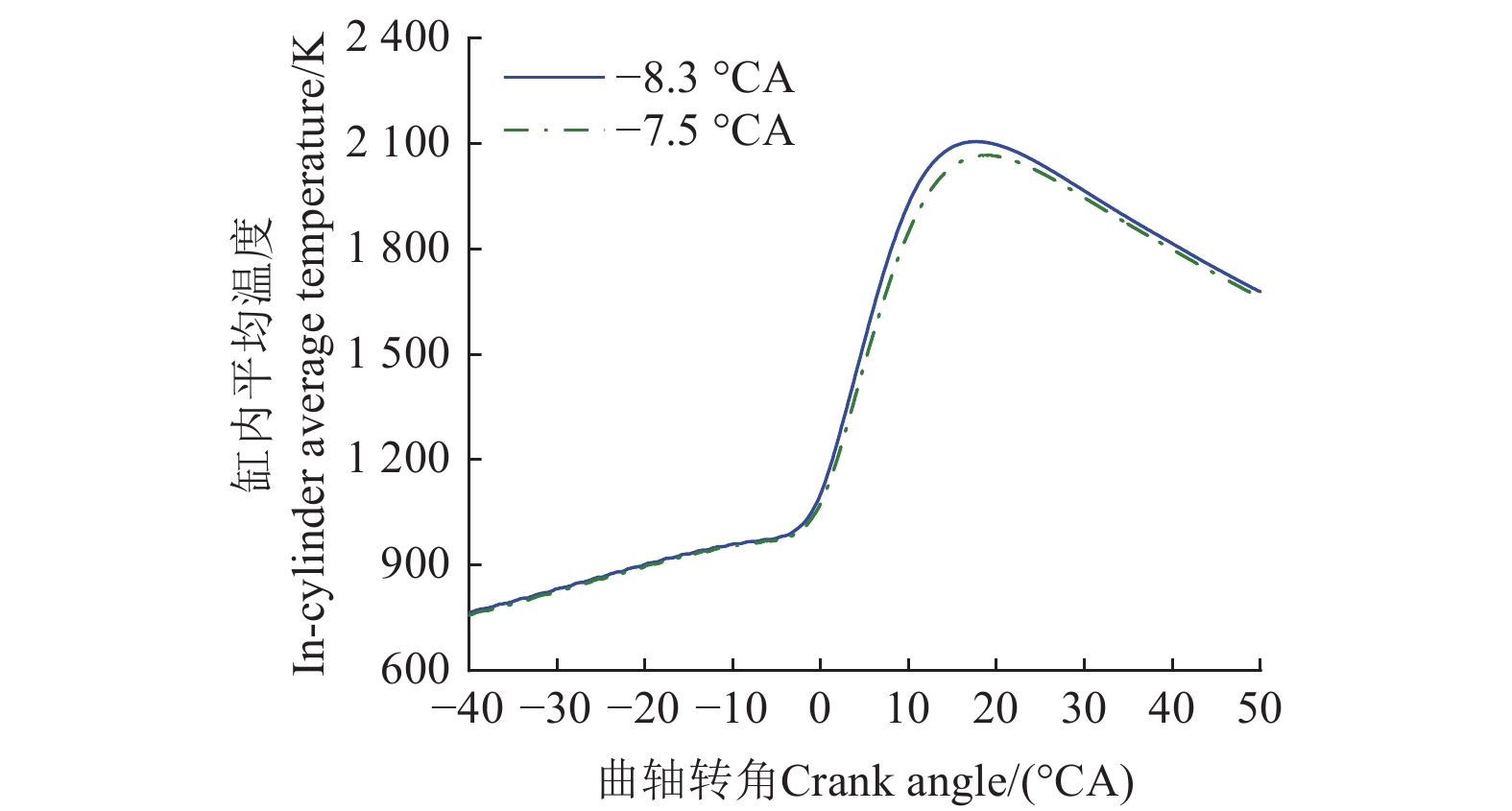

Abstract:This study aims to explore the performance and combustion characteristics of a direct-injection hydrogen engine. A 36.8 kW non-road China IV diesel engine was modified to alter its intake manifold and cylinder head. A four-stroke hydrogen engine was then developed to investigate its performance under full-load conditions. A systematic investigation was also implemented to explore the impact of ignition timing on its combustion characteristics and knocking tendency. The hydrogen engine was operated stably to fully meet the requirements of the power output during testing. The throttles were also kept fully open. The optimal ignition timing was selected for each full-load condition. While the engine speed was varied from the idle at 800 r/min to the rated speed at 2 500 r/min. The test results indicated that the torque initially increased and then decreased, as the speed increased within the entire speed range of the hydrogen engine, thus reaching the maximum of 147 N·m at 1 500 r/min. The maximum power of 36.8 kW was achieved at the rated speed of 2 500 r/min. The hydrogen consumption ranged between 90 and 95 g/(kW·h) under specific full-load conditions. The exhaust temperature also rose, as the speed and load increased. The coefficient of variation of the mean indicated pressure (COVIMEP) was highest at the rated power, but still only 5.36%, indicating stable engine operation. At the maximum torque operating point, the ignition timing was varied to analyze its impact on the combustion characteristics of the hydrogen engine. Once the ignition timing was advanced from -7.5 to -8.3 °CA, the combustion centroid was shifted earlier from 6.7 °CA after the top dead center (ATDC) to 6.1 °CA ATDC. The duration of the full combustion decreased from 13.4 to 12.6 °CA, whereas, the peak heat release rate increased from 67.3 to 72.0 J/(°CA). The process was more concentrated closer to the constant-volume combustion. The more intense in-cylinder combustion was then obtained to rapidly increase the in-cylinder pressure and temperature. The fuel combustion rate was accelerated to cause instability in the combustion process between cycles, which further increased the COVIMEP. Additionally, the ignition timing increased the crank angle duration of the in-cylinder temperatures above 1 800 K from 30.7 °CA to 33.1 °CA. The longer durations of the high in-cylinder temperatures were observed to increase the NOx emissions from 11.51 to 12.03 g/(kW·h). The operating condition was selected with the average maximum amplitude of pressure oscillations (MAPO) under external characteristic conditions (1 400 r/min, throttle fully open). The ignition timing was then varied to analyze the effect of the ignition timing on the knock characteristics. The ignition timing increased the average MAPO of the hydrogen engine from 0.015 to 0.020 MPa, and the peak in-cylinder pressure from 5.99 to 6.16 MPa. The individual knocking cycles revealed that the knocking depended mainly on the high in-cylinder temperatures, which induced the spontaneous ignition of unburned mixtures. The ignition timing caused more fuel to combust and release heat before the top dead center. The increasing degree of the constant-volume combustion raised the in-cylinder temperatures and pressures. The increasing tendency was found for the spontaneous ignition of the unburned mixtures, thereby increasing the knocking tendency of the hydrogen engine.

-

0. 引 言

随着工业化和现代化的进程加快,全球对能源的需求量不断增加。愈发严重的环境污染,使得发展可替代传统化石能源(煤、石油、天然气等)的清洁能源备受研究人员的关注[1-3]。氢气作为一种不含碳的燃料,其完全燃烧产物只有水,具有零碳排放的显著优势[4],是一种良好的清洁燃料,并且氢可以利用可再生能源(太阳能、风能)发电后电解水制取,所以利用氢燃料是应对全球能源与环境问题的可靠解决方案之一[5-6]。同时,氢气具有的质量能量密度高、可燃极限宽、点火能量小和火焰传播速度快等优点[7-8]。但氢气作为发动机燃料可能存在NOx排放高、易发生早燃、爆震等缺点[9-10]。这可能导致发动机的各项性能指标恶化,严重时甚至会导致发动机损坏[8,11]。

在之前的研究中,研究人员通过试验和数值模拟研究了氢发动机的燃烧特性。LUO等[12]研究了进气道喷射氢发动机爆震的诱发因素,发现氢发动机的回火提高了点火时混合气的初始温度,会增加爆震发生的可能性。DHYANI等[13]在氢燃料火花点火发动机上研究了不同参数对回火的影响。研究发现,延迟点火定时和延迟喷氢正时可以减少回火的发生。相较于易发生回火的进气道喷射氢发动机,缸内直喷氢发动机因其高功率密度、高热效率和无回火发生等优点,更令研究人员关注[14-16]。MOHAMMADI等[8]在缸内直喷氢发动机上研究了大负荷工况下氢发动机的性能。结果表明,压缩冲程期间的氢气直接喷射可以有效防止回火的发生,并且可获得较高的热效率和更大的输出功率。LI等[17]对缸内直喷氢发动机的循环变动特性进行了试验研究。研究发现,随着转速的升高氢发动机的循环变动率增大,随着负荷的增大循环变动率降低。TSUJIMURA等[18]发现,较低的喷氢压力会延长喷射持续时间,导致混合气分布不均匀,从而加速燃烧过程,并且由于混合气中存在浓混合气,导致NOx的排放量升高。HUANG等[19]利用三维仿真研究了喷氢压力和喷氢正时对直喷氢发动机混合气形成和燃烧特性的影响,结果表明,在一定的喷氢压力下,随着喷氢正时的推迟,混合气分布均匀性变差,这也导致了火焰传播速度降低。FU等[20]通过试验研究了过量空气系数、点火定时和喷氢正时对低负荷氢发动机燃烧和排放性能的影响。发现在较低转速下,稀薄的混合气和适当的点火定时可以表现出较高的热效率。但是缸内直喷氢发动机仍存在爆震发生的可能。KAWAHARA等[21]通过高速摄像机看到了气缸内压力波的振荡,并且发现未燃混合气的质量对爆震强度有明显的影响。YANG[22]通过CFD分析了氢发动机爆震过程中的压力波和火焰传播过程。由末端混合气自燃引起的初始压力波不断传播,扰动了火焰锋面附近的未燃气体,促进了未燃气体的压力和温度振荡。LI等[23]通过数值模拟,重点研究了不同当量比和压缩比下缸内直喷氢发动机的燃烧和爆震特性。结果表明,在高压缩比时爆震强度对当量比的敏感性更大。LAI等[24]以平均最大压力振荡幅值作为爆震评价指标,研究了喷氢压力、当量比和点火定时等参数对缸内直喷氢发动机爆震的影响。结果表明,随着点火定时的提前,火花塞处混合气的氢气浓度更高,分布更加集中,燃烧持续时间更短,燃烧温度升高。LOU等[25]基于台架试验和一维仿真研究了发动机转速、点火定时等因素对氢发动机爆震的影响。研究发现,发动机在较低转速下发生爆震的可能性较大,而且随着点火定时的提前发动机爆震倾向先增大后减小。MOHAMADREZA等[26]基于一台直喷氢发动机,通过数值模拟和试验研究发现,相对最佳点火定时提前点火会导致压缩负功增加,降低了氢发动机的指示热效率。

在上述文献中,研究人员通过试验和仿真对氢发动机的燃烧性能和爆震进行了大量研究,并且是在原汽油机(通常为增压汽油机)的基础上稍加改造且用于乘用车的氢发动机,其发动机的转速较高。而非道路用自然吸气氢发动机至今尚未见到报道。因此,我们开发了一款非道路用自然吸气氢发动机,并对压缩比、当量比、点火定时和喷氢正时等参数进行了优化匹配。其中,点火定时对氢发动机的燃烧过程有重要影响。因此,本文重点研究了外特性工况下缸内直喷氢发动机的性能,以及点火定时对氢发动机燃烧特性和爆震的影响。

1. 试验装置与方法

1.1 试验装置

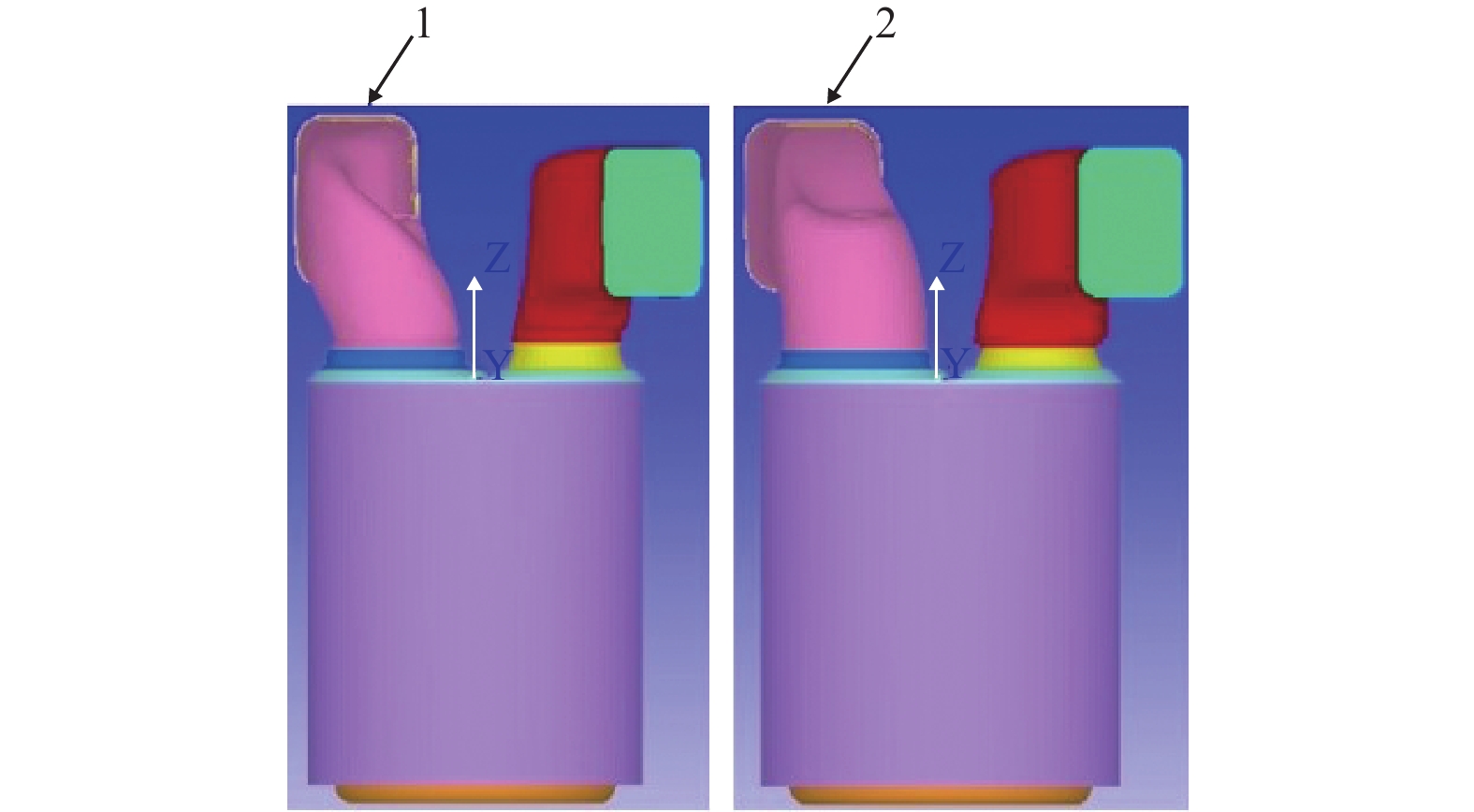

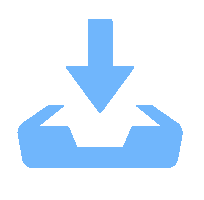

本文是基于一台直列四缸非道路自然吸气柴油机开发的缸内直喷氢发动机。对自然吸气燃氢发动机而言,最大的困难是在保证其原柴油机功率的前提下,不发生爆震等异常燃烧并同时降低NOx的生成,这就要求其过量空气系数尽可能大。由于氢气具有非常高的扩散系数,我们对进气道进行了优化,即将原机的螺旋进气道改为低涡流进气道(如图1所示),即缸内涡流比从2.5减小到了1.0以下,这样可以提高发动机的容积效率,再通过燃烧室和喷嘴的优化匹配(如图2所示),使得在火花点火时刻形成更加均匀的混合气,即使有一些不均匀,也将局部较浓的混合气靠近火花塞,这样既保证正常点火,也降低了异常燃烧的发生。

对氢发动机具体的改造还包括:尽量将火花塞布置在气缸中心附近以缩短火焰传播距离;同时,采用侧置26°的氢喷嘴和倾斜3°的活塞顶,使喷射中期的氢气束正对燃烧室中心。从而使火花塞点火时尽量使混合气均匀或火花塞附近产生稍浓的混合气。

本文统一把压缩上止点定义为0 ℃A,压缩上止点前为负值,压缩上止点后为正值。而试验所用氢发动机的详细参数见表1。

表 1 氢内燃发动机主要结构参数Table 1. Main structural parameters of hydrogen internal combustion engine参数Parameters 数值Values 发动机型式

Engine type直列4缸、四冲程、水冷 供氢方式

Hydrogen supply method缸内直喷 喷氢压力

Hydrogen injection pressure/MPa25 缸径

Cylinder bore/mm93 气门数量

Number of valves2 行程

Stroke/mm102 连杆长度

Connecting rod length/mm152 压缩比

Compression ratio10 排量

Displacement/L2.77 标定功率

Rated power/kW36.8 进气门关闭时刻

Intake valve closing angle/℃A−147 排气门开启时刻

Exhaust valve opening angle/℃A140 1.2 试验方法与数据处理

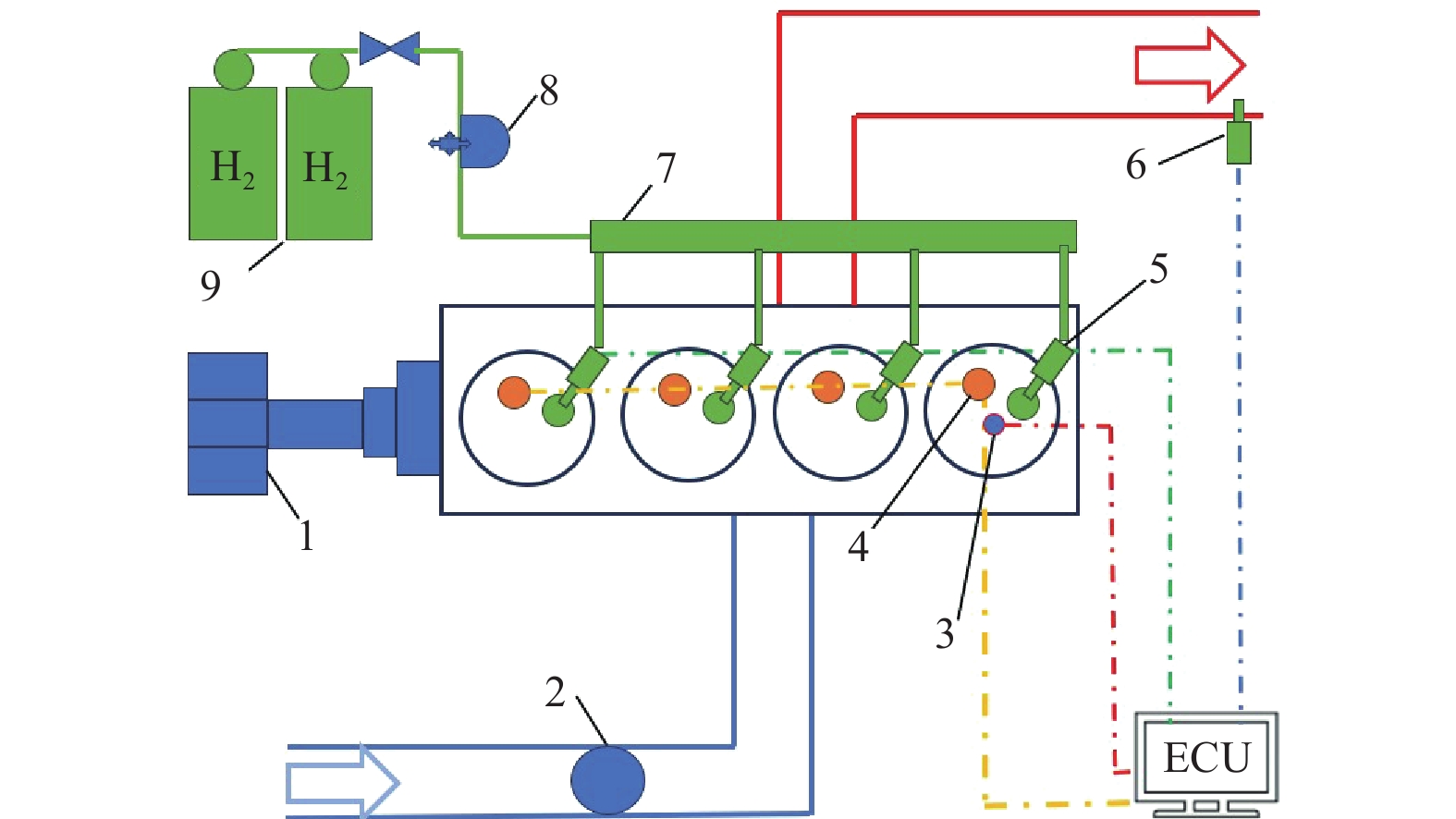

试验用的测功机为AVL生产的一台电力测功机,最大功率为160 kW,转速控制误差≤±1 r/min。测功机控制系统型号为PUMAOPEN 2.0,并采用AVL公司的燃烧分析仪。图3为发动机台架示意图,试验用的主要仪器设备规格与型号见表2,其中试验所用氢气流量计的测量精度为±0.5%。

![]() 图 3 发动机台架示意图1. 测功机 2. 节气门 3. 缸压传感器 4. 火花塞 5. 氢喷嘴 6. 氧传感器7. 氢轨 8. 氢气流量计 9.储氢罐Figure 3. Schematic diagram of an engine test bench1. Dynamometer 2. Throttle valve 3. Cylinder pressure sensor 4. Spark plug 5. Hydrogen injection nozzle 6. Oxygen sensor 7. Hydrogen rail 8. Hydrogen flow meter 9. Hydrogen storage tank表 2 台架测控系统主要仪器型号Table 2. Bench measurement and control system main instrument models

图 3 发动机台架示意图1. 测功机 2. 节气门 3. 缸压传感器 4. 火花塞 5. 氢喷嘴 6. 氧传感器7. 氢轨 8. 氢气流量计 9.储氢罐Figure 3. Schematic diagram of an engine test bench1. Dynamometer 2. Throttle valve 3. Cylinder pressure sensor 4. Spark plug 5. Hydrogen injection nozzle 6. Oxygen sensor 7. Hydrogen rail 8. Hydrogen flow meter 9. Hydrogen storage tank表 2 台架测控系统主要仪器型号Table 2. Bench measurement and control system main instrument models设备名称

Equipment name设备型号Equipment model 电力测功机

Electric dynamometer160 kW 测功机控制系统

Dynamometer control systemPUMAOPEN 2.0 燃烧分析仪

Combustion analyzer631 氢气流量计

Hydrogen flow meterCMFSO15P 本试验在压缩冲程上止点前130.5 ℃A控制喷嘴向缸内喷射氢气,取发动机转速从怠速800 r/min到标定转速2 500 r/min,保持节气门全开的满负荷工况,选取最佳点火定时(minimum advance for best torque, MBT),以此研究氢发动机在各转速最大负荷条件下的性能,具体试验工况见表3。保持氢发动机在各工况下稳定工作一段时间后,测量并记录每个工况下100个缸内压力循环的试验数据。

表 3 外特性试验工况Table 3. External characteristic test conditions转速

Speed/(r·min−1)扭矩

Torque/N·m当量比

Equivalence ratio最佳点火定时

MBT800 123.9 0.80 -9.8 1 200 128.3 0.59 -12.8 1 500 147.0 0.69 -7.5 1 800 146.0 0.67 -5.3 2 200 140.7 0.60 -11.3 2 500 140.6 0.61 -9.8 在各种确定爆震强度的方法中,基于缸内燃烧压力波动的方法是比较准确和可信的[27]。本文利用缸内压力传感器采集缸压数据,缸内压力的采样频率为0.1℃A,同时采用5~25 kHz的带通滤波过滤缸内压力,以此分析燃烧过程。定义滤波后压力振荡的最大绝对振幅(maximum amplitude of pressure oscillations, MAPO)为爆震强度[20,24],定义同一工况所有循环的平均MAPO以表征整个工况的爆震强度。

$$ \overline K {\text{ = }}\frac{1}{N}\sum\limits_{{\text{i = 1}}}^N {{K_i}} $$ (1) 式中N为循环数,$\overline K $表示平均MAPO,Ki为单个循环的最大压力振荡幅值,MPa。

在本研究中,认为平均MAPO大于0.1 MPa时发生了爆震[23,28],单个循环的MAPO超过0.1 MPa认为该循环发生了爆震[29-31]。

此外通过计算热释放率(heat release rate, HRR)、燃烧持续期(定义缸内累积放热量从10%~90%所持续的曲轴转角,CA10-90)和燃烧重心(定义循环累积放热量达到50%的曲轴转角,CA50),以及压力升高率(pressure rise rate)以此分析发动机的燃烧特性。

本研究以平均指示压力循环变动率(coefficients of variation of indicated mean effective pressure,COVIMEP)来表征发动机的燃烧稳定性,其计算式如下:

$$ A = \frac{\sigma }{{\overline x }} $$ (2) $$ \sigma = \sqrt {\frac{1}{{N - 1}}\sum\limits_{i = 1}^N {{{\left( {{x_i} - \overline x } \right)}^2}} } $$ (3) $$ \overline x = \frac{1}{N}\sum\limits_{i = 1}^N {{x_i}} $$ (4) 式(2)~(4)中A为平均指示压力的循环变动率;σ为平均指示压力的标准差,MPa;$\overline x $为平均指示压力的平均值,MPa;N为循环数,本试验N取100。

根据缸内压力计算缸内温度,计算式如下:

$$ T_i=\frac{p_iV_i}{nR} $$ (5) $$ n=\frac{p_sV_H}{RT_s} $$ (6) 式中Ti为缸内平均温度,K;Vi为缸内容积,m3;pi为缸内压力,Pa;n为缸内混合气的物质的量,mol;R为气体常数,J/(mol·K);VH为发动机的工作容积,m3;Ts为进气歧管温度,K;ps为进气歧管压力,Pa。

2. 结果与分析

2.1 氢发动机性能

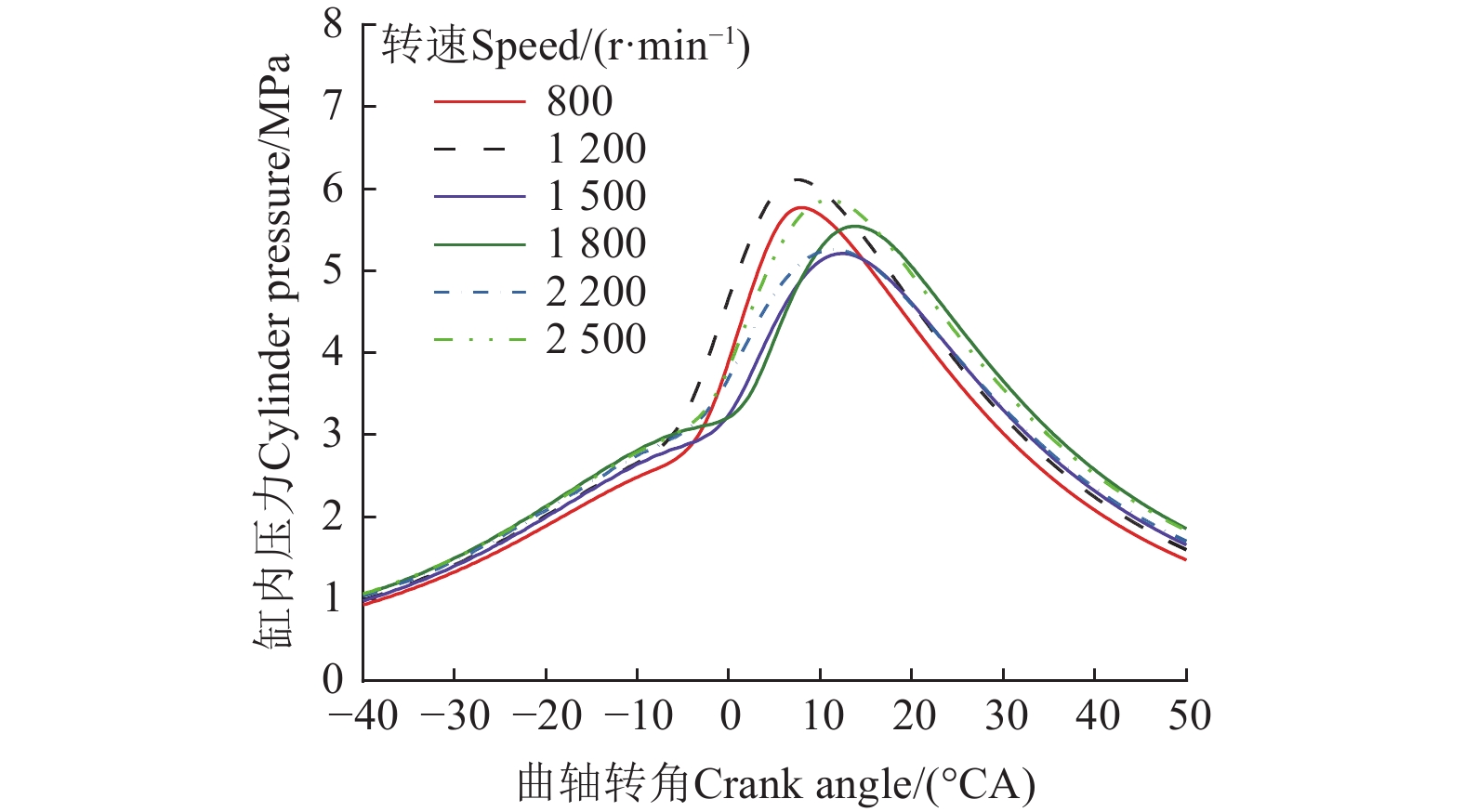

图4为外特性工况下的缸内压力曲线,可以看出最高的缸内峰值压力为6.11 MPa,所处曲轴转角为上止点后7.6 ℃A,发生在转速为1 200 r/min、扭矩为128.3 N·m的工况。这是因为此时的点火定时为-12.8 ℃A,点火定时稍有提前,导致更多燃料在上止点附近燃烧所致,这也使缸内的燃烧定容度提高,从而降低了氢气的消耗率,提高了该工况的热效率。从图5的比氢耗曲线可以看出,如果提前点火,会使压缩负功增加,缸内峰值压力会进一步提高,使动力性和经济性恶化。

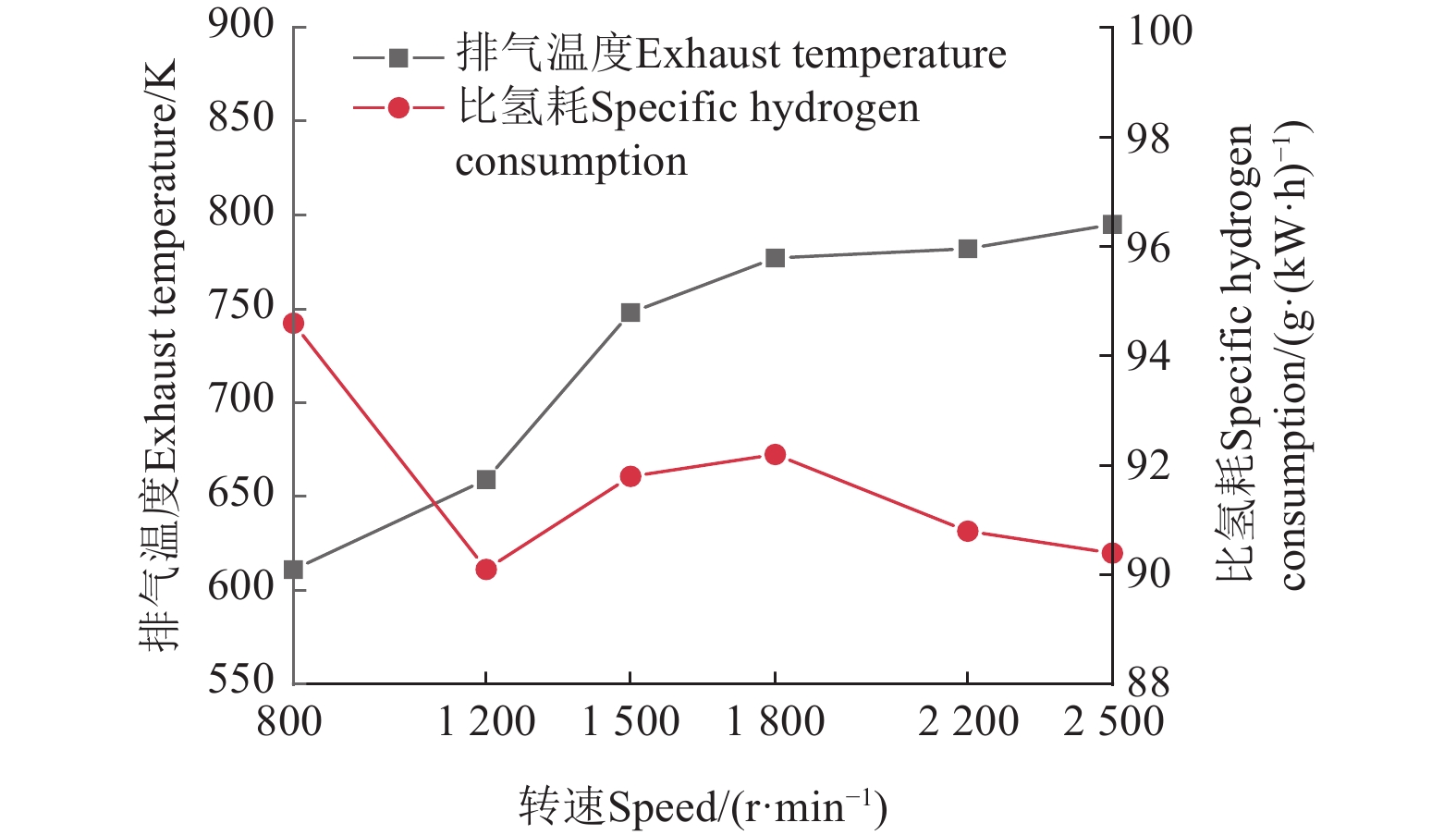

图5为外特性工况下的排气温度和比氢耗。可见,随着转速和负荷的增大,排气温度增大。而外特性特定工况下的比氢耗维持在90~95 g/(kW·h)。比氢耗随转速变化的曲线在1 500、1 800 r/min时出现“上凸”,这是为了保证在不发生爆震的前提下尽量增大氢发动机的扭矩输出,通过适当增加喷氢脉宽以形成更浓的混合气,这点也可以从当量比的数值变化看出。

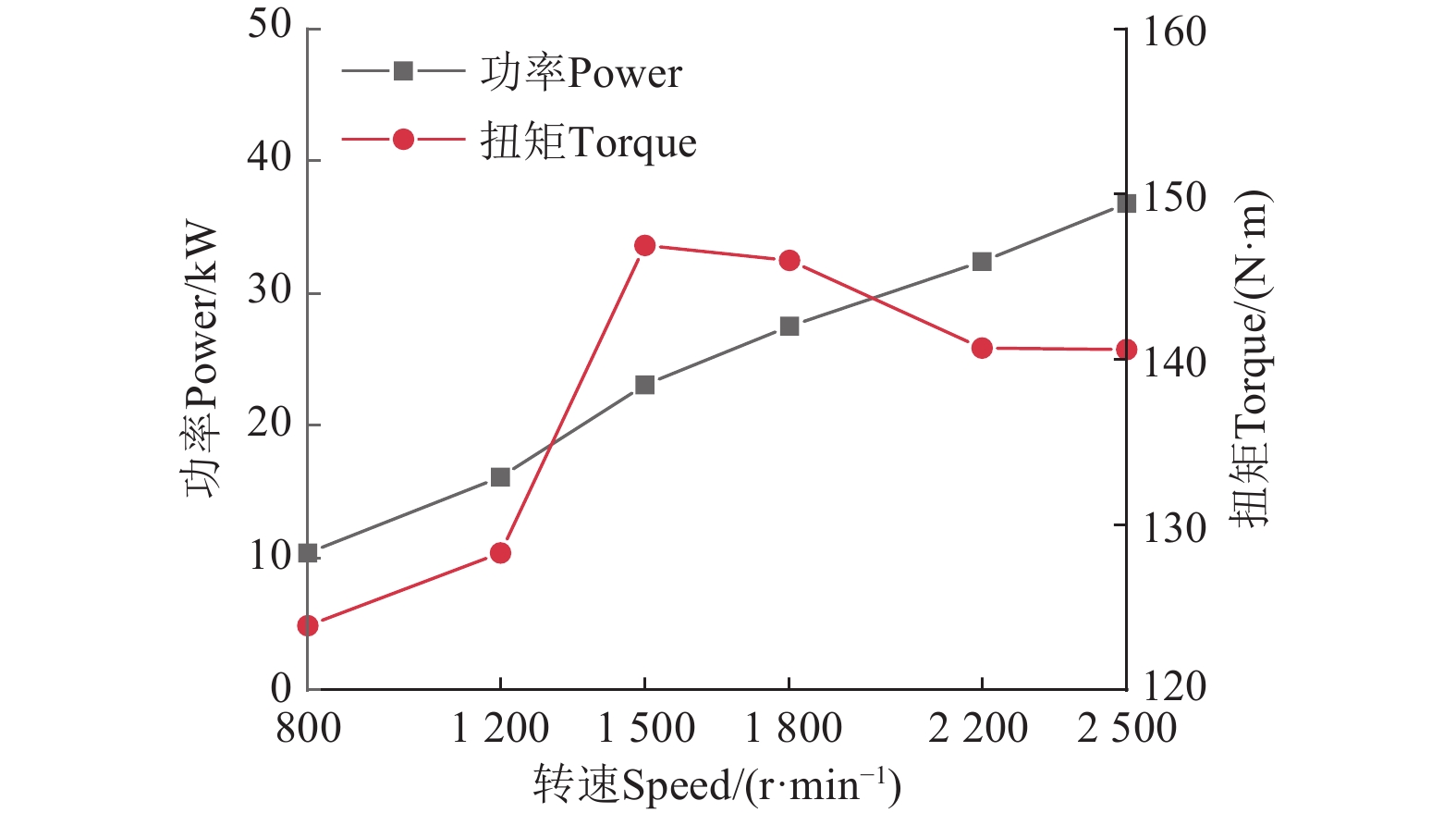

图6为不同外特性工况下的功率和扭矩,随着转速的增加氢发动机的扭矩先增加后减少,在1 500 r/min时扭矩达到最大值147 N·m。然而,此工况下的缸内峰值压力仅为5.21 MPa,所处曲轴转角为上止点后12.5 ℃A,是各外特性曲线上缸内峰值压力最小、所处位置较为靠后的工况。这主要是因为外特性上的该工况是试验工况中除了800 r/min这一低速工况以外混合气最浓的工况,为了降低爆震风险,只能靠推迟点火实现。而发动机功率则随着转速的增大而增大,在标定转速2 500 r/min时达到标定功率36.8 kW。此时氢发动机的过量空气系数为1.64,并且无明显的异常燃烧发生。

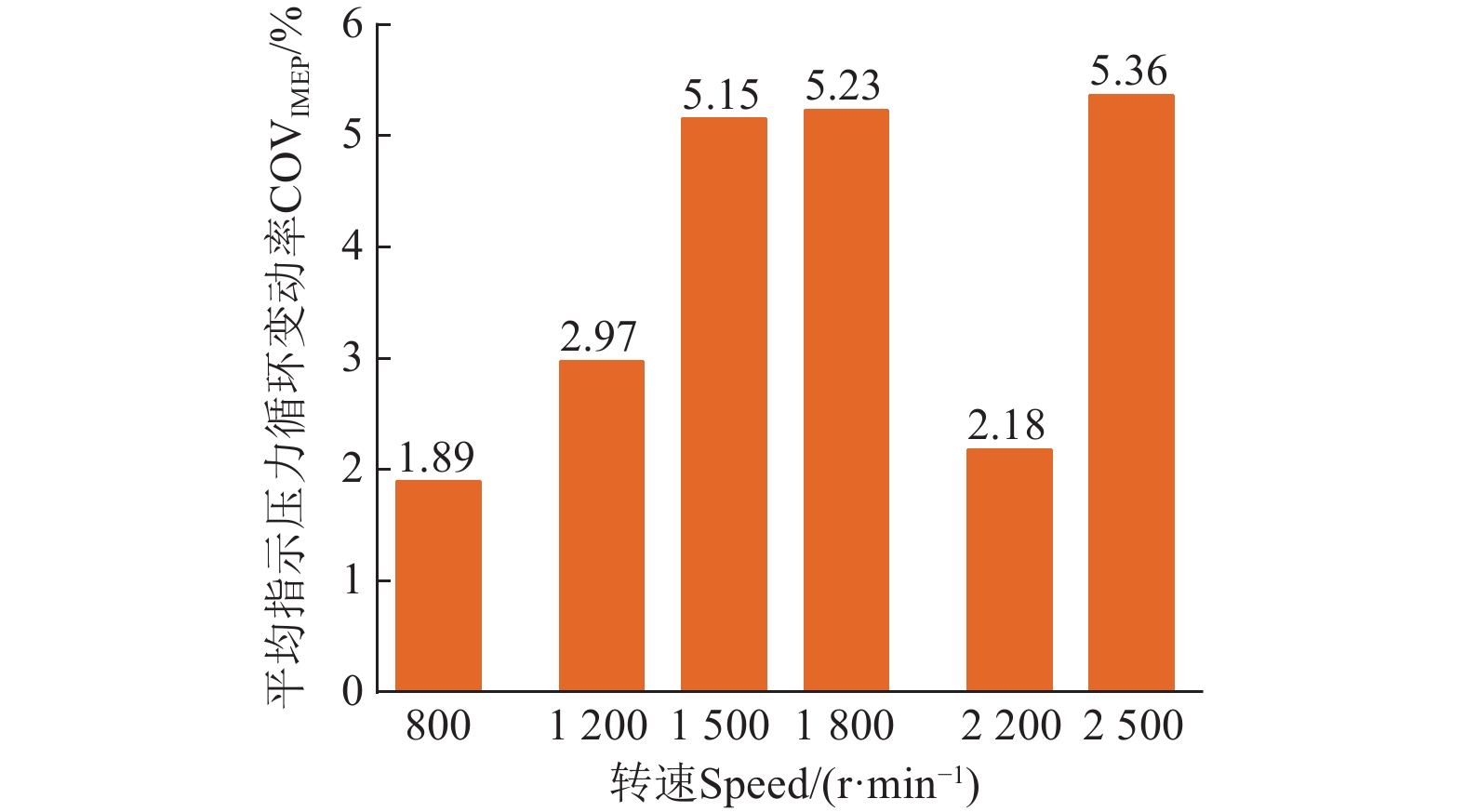

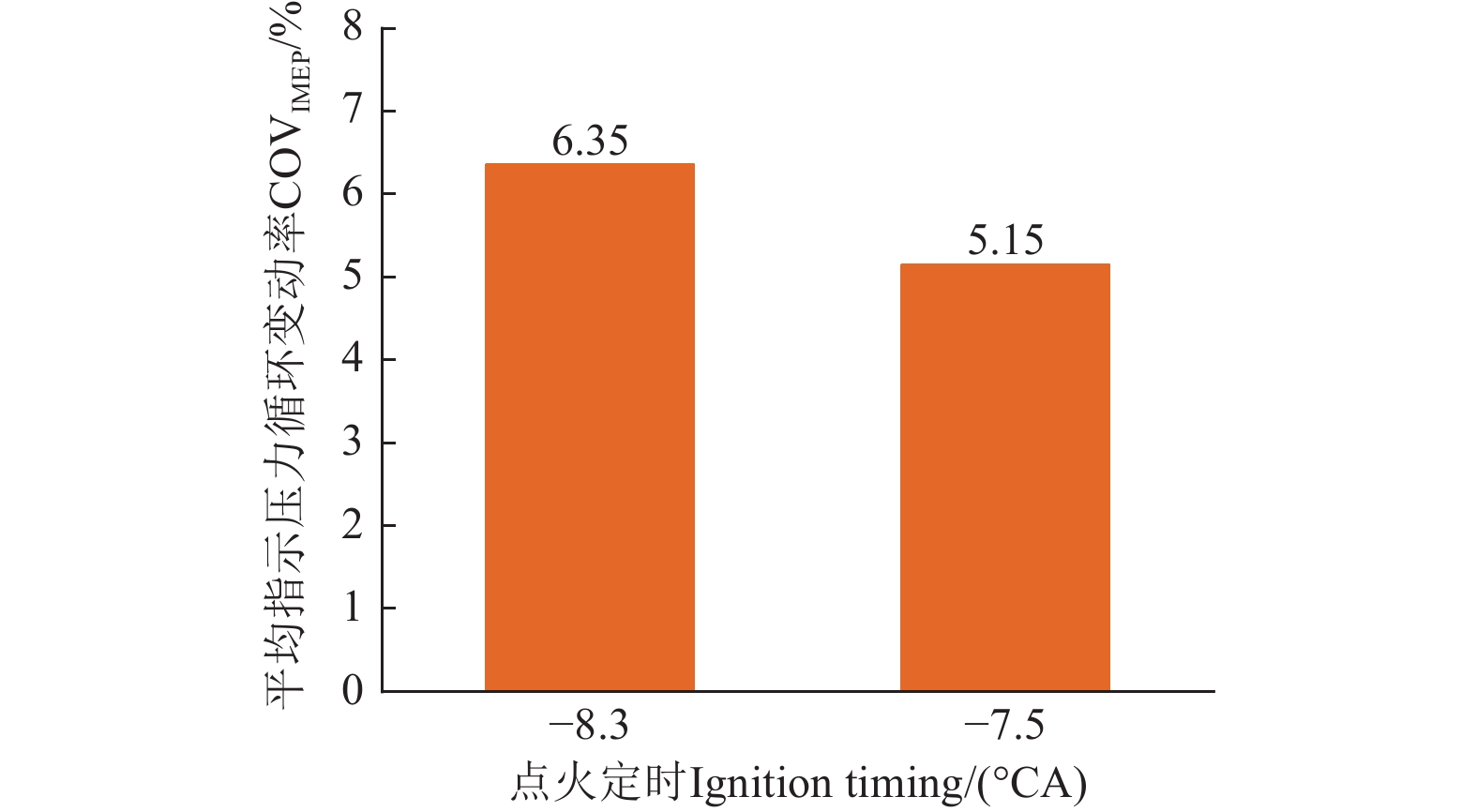

图7为不同转速下氢发动机的平均指示压力循环变动率,在800 r/min、123.9 N·m这一最低转速工况时最小,在标定工况2 500 r/min、140.6 N·m时最高。而平均指示压力循环变动率的最高值仅为5.36 %,可见,在外特性曲线上,氢发动机不仅满足功率的输出需求,并且不发生爆震等不正常燃烧,氢发动机的运转较为稳定。而对于较小负荷的工况,在喷氢压力一定时,可以通过调节喷氢脉宽,使过量空气系数增大(达到2~4的范围),这时氢发动机几乎不会发生不正常燃烧和较大的循环变动。因此,可以使氢发动机在每一个工况均稳定运转。

2.2 点火定时对燃烧特性的影响

对于缸内直喷发动机,点火定时对发动机的燃烧过程有明显影响。选取氢发动机的最大扭矩点1 500 r/min,147 N·m,在保证发动机功率输出和当量比相同的情况下,选取了两个点火定时以研究点火定时对燃烧特性的影响。之所以选择两个点火定时,是因为过大或过小的点火定时都会降低扭矩,且更易发生不正常燃烧。

图8给出了在1 500 r/min,147 N·m时,不同点火定时下的缸内压力和放热率。可见,在1 500 r/min,147 N·m时随着点火定时从−7.5提前到−8.3℃A,缸内峰值压力从5.21增大到5.41 MPa,缸内峰值压力对应的曲轴转角从12.5提前到11.6℃A。放热率峰值从67.3增大到72.0 J/(℃A),并且放热率峰值对应的曲轴转角都为5.0 ℃A。这是因为随着点火定时的提前,点火延迟期(定义为从点火开始到累积放热量10%的曲轴转角)从8.7 ℃A延长到了9.1℃A,导致燃烧稍有滞后。同时,点火定时仅提前了0.8 ℃A,考虑到燃烧放热率是由100个循环平均后得到的,以及氢发动机燃烧过程的复杂性,放热率峰值对应的曲轴转角可能没有明显变化。并且此试验工况下的过量空气系数在外特性曲线上较小(为1.45),这会增大循环变动,从而导致放热率峰值对应的时刻产生波动。综合上述因素,点火定时提前放热率峰值对应的曲轴转角相差无几。

从图9可以看出,随着点火定时的提前最大压力升高率从0.24增大到0.26 MPa/℃A,其对应曲轴转角从3.0提前到2.8℃A。这是因为缸内压力在燃料燃烧和活塞压缩的共同作用下,随着点火定时的提前,更多燃料在上止点前燃烧,释放更多的能量,缸内压力迅速升高,压力升高率峰值增大并提前。

由图10也可以看出,随着点火定时的提前,缸内混合气提前被点燃,使燃料的燃烧在更靠近上止点时发生,燃烧重心从6.7提前到6.1℃A,加上活塞的压缩导致了缸内峰值压力的升高。并且,燃烧持续期随着点火定时的提前从13.4减少到12.6 ℃A,燃烧更加集中,热量累积加快,使放热率峰值增大。但这也导致了在上止点前燃烧的燃料稍多,燃料的利用率稍有降低,比氢耗从91.8增大到92.1 g/kW·h。

并且如图11所示,随着点火定时的提前缸内最高燃烧温度从2 067 K增大到2 106 K,其对应曲轴转角从19提前到17.6 ℃A。而1 800 K以上的缸内温度所持续的曲轴转角从30.7增加到33.1 ℃A,缸内高温持续时间更长,导致NOX生成量从11.51增大到了12.03 g/(kW·h)。

图12给出了循环变动率随点火定时的变化趋势,可以看出,随着点火定时的提前,COVIMEP从5.15%升高到了6.35%。这是因为点火定时提前,燃烧重心更靠近上止点,燃烧持续期减小,使燃烧过程更接近定容燃烧,单位体积内热量释放更多,缸内压力和温度迅速升高。而迅速升高的缸内温度和压力会加快燃料的燃烧速率,导致燃料剧烈燃烧,加之不同循环间缸内混合气和缸内温度压力的差异,导致不同循环间燃烧过程不稳定,平均指示压力循环变动率增大。

2.3 点火定时对爆震的影响

爆震是缸内直喷氢发动机的一种异常燃烧现象,对发动机的性能和使用寿命有很大影响。为了研究缸内直喷氢发动机爆震发生的原因和影响因素,选取平均MAPO最大的工况(1 400 r/min、节气门全开)通过改变点火定时,以分析点火定时对爆震特性的影响。

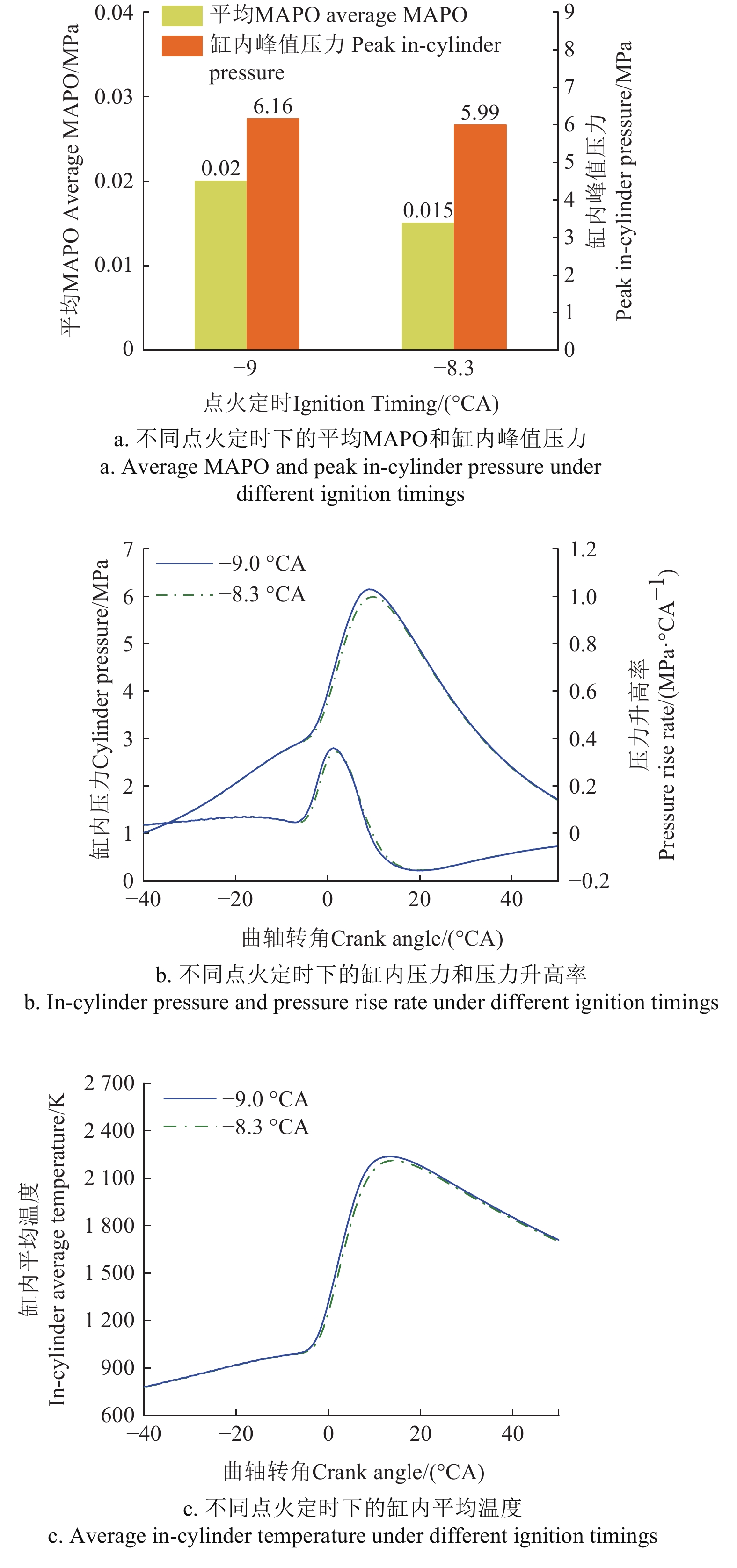

图13a给出了发动机在1 400 r/min、节气门全开时的平均MAPO和缸内峰值压力随点火定时的变化。可以看出,随着点火正定时的提前,平均MAPO从0.015增大到0.020 MPa,缸内峰值压力从5.99增大到6.16 MPa。根据爆震发生的定义,两个点火定时下的平均MAPO的值均小于0.1 MPa,氢发动机未发生爆震,但是平均MAPO的增大意味着随着点火定时的提前氢发动机的爆震倾向增大。

图13b为1 400 r/min、节气门全开时100个循环平均后的缸内压力和压力升高率曲线。可以看出,随着点火定时从−8.3提前到−9.0 ℃A,缸内峰值压力对应的曲轴转角从9.7提前到8.8 ℃A;压力升高率峰值从0.345增大到0.36 MPa/℃A,对应曲轴转角从1.7提前到1.2 ℃A。可见,随着点火定时的提前缸内压力峰值和压力升高率峰值升高且更靠近上止点。结合图13c可见,随着点火定时的提前,更多的燃料在上止点前燃烧放热,燃烧定容度有所增大,缸内平均温度升高,使得爆震倾向增大。

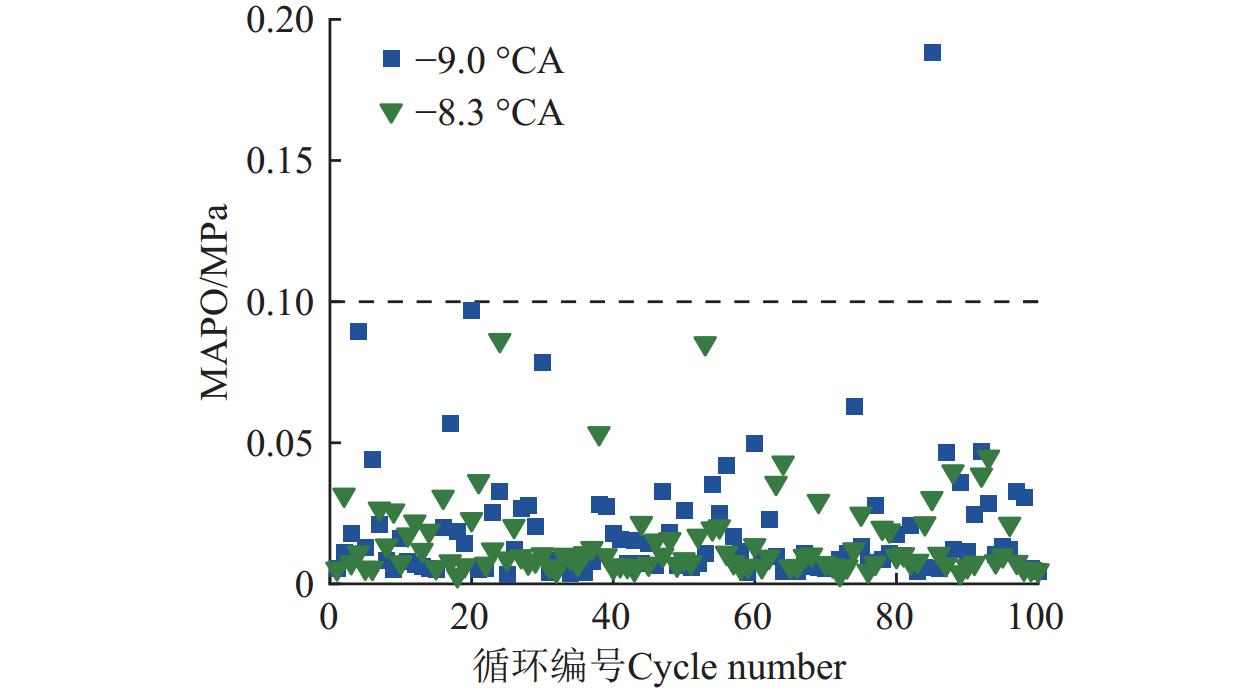

图14是1 400 r/min、节气门全开时,点火定时分别为−8.3和−9.0 ℃A时100个连续循环的详细MAPO分布。将每个工况100个连续循环中MAPO大于0.1 MPa的循环占总循环数的比例定义为爆震概率。可以看出,对于该工况,点火定时为−8.3 ℃A时,MAPO都小于0.1 MPa,无爆震发生;点火定时为−9.0℃A时存在MAPO大于0.1 MPa的点,爆震概率为1%。可见,随着点火定时从−8.3 ℃A提前到−9.0 ℃A,爆震概率增大。单个循环的MAPO大多分布在0.01 MPa附近,但是在点火定时为−9.0 ℃A时,第85循环的MAPO为0.188 MPa,本文认为在此循环发生了爆震。

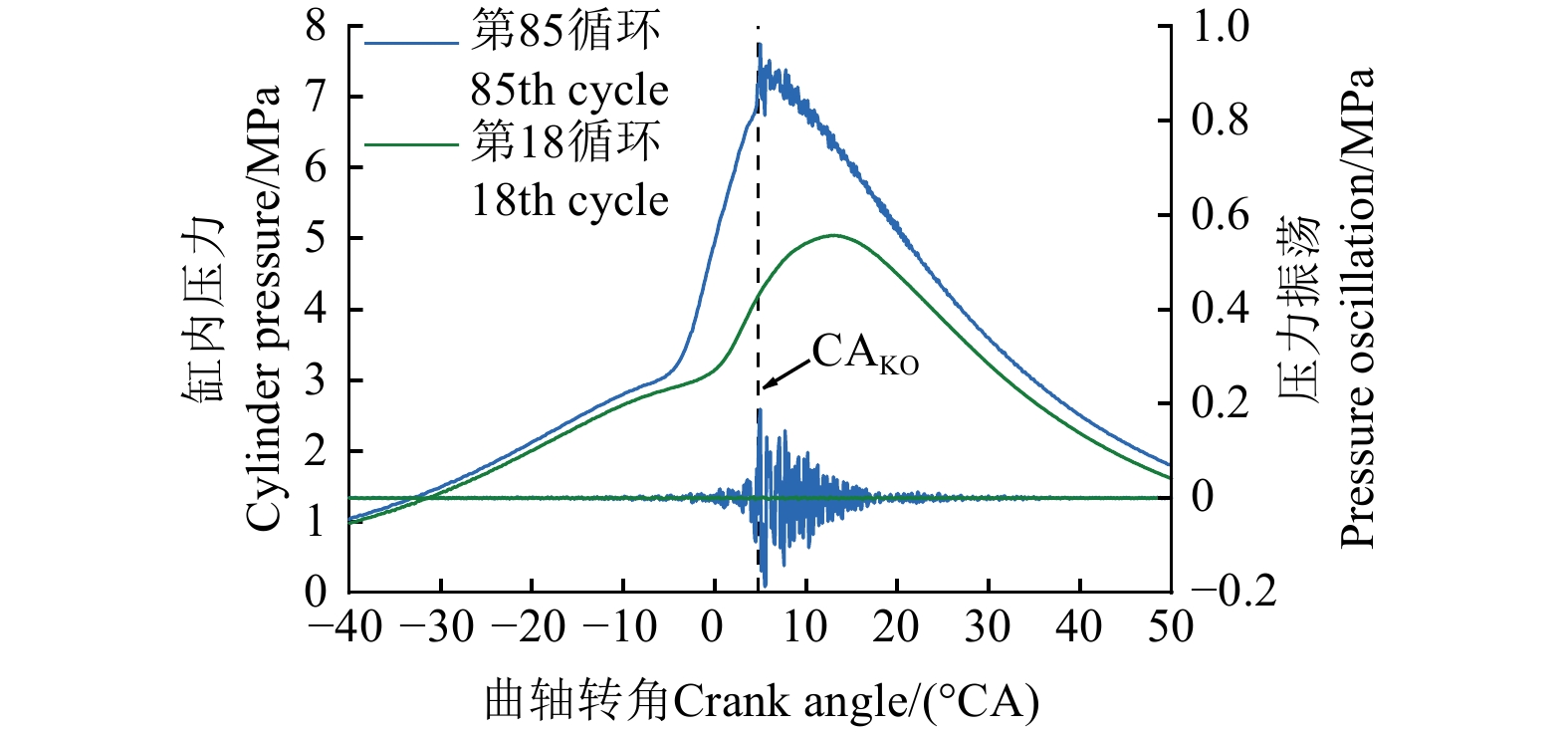

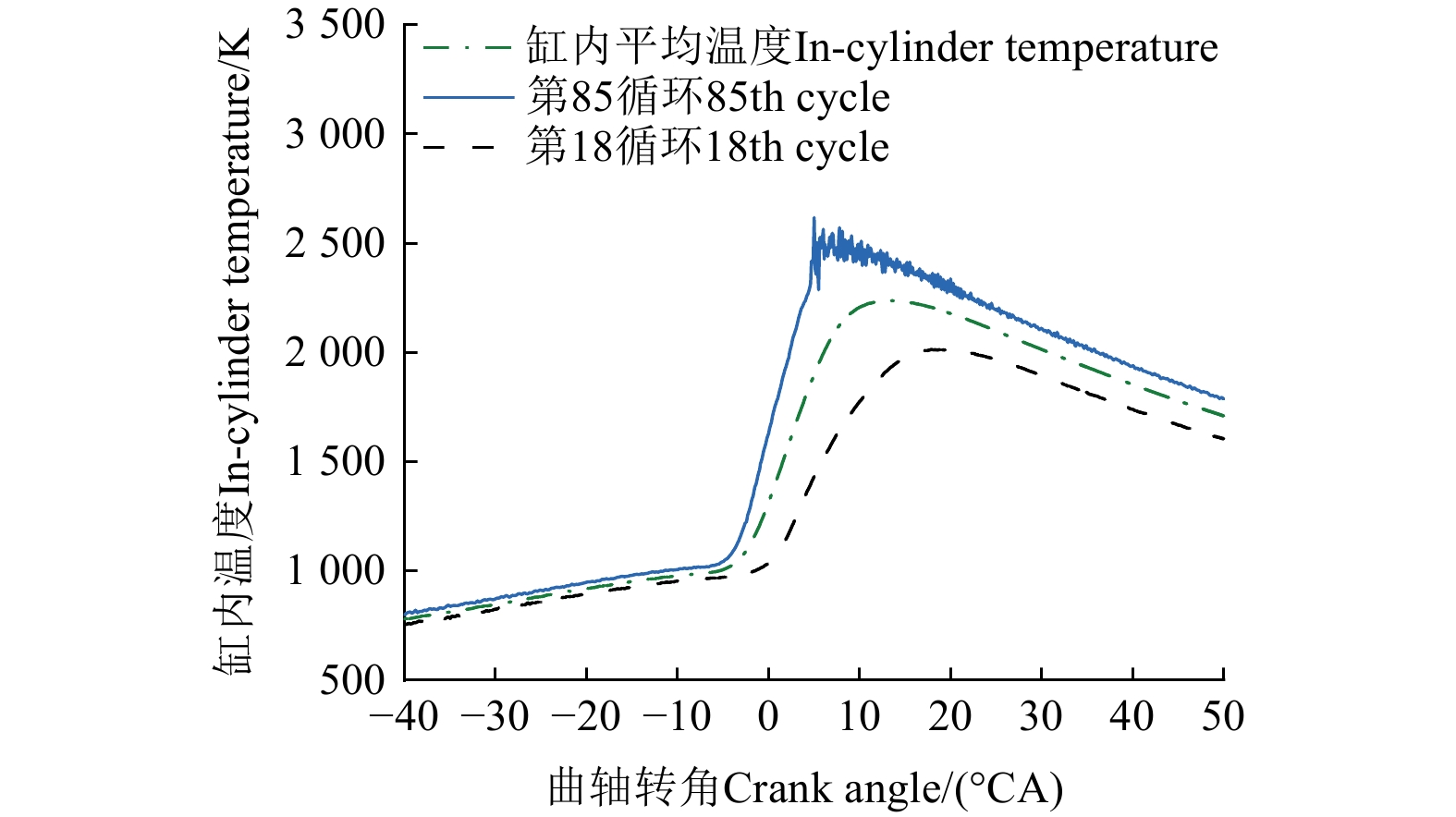

为了深入分析点火定时变化引起爆震倾向变化的原因,以1 400 r/min,点火定时为−9.0 ℃A时的第85循环和第18循环为例,分析了爆震发生的原因。图15为第85、18循的缸内压力以及相应的压力振荡曲线。其中第85循环为此点火定时下100个循环中MAPO最大的循环,第18循环的MAPO则最小,为0.003 MPa。从该图可以看出,第85循环的缸内压力曲线存在明显波动,缸内压力峰值为7.51 MPa,对比此工况的缸内平均压力峰值6.16 MPa,可见此循环的爆震表现明显。而第18循环的压力振荡很小,缸内压力峰值仅为5.04 MPa,此循环未发生爆震。

CAKO (knock onset)定义为爆震发生时刻的曲轴转角,此刻的压力振荡剧烈,压力振荡幅值为0.103 MPa,对应的曲轴转角为4.8 ℃A,认为此刻为第85循环爆震开始的曲轴转角。对比此工况下的燃烧重心3.6 ℃A,可见爆震的发生处在整个燃烧过程的中后期。结合图16中在−9.0 ℃A的点火定时下,100个循环的缸内平均温度和第85、18循环的缸内温度变化,发生爆震循环的缸内温度远高于此工况的缸内平均温度,并且在发生压力振荡的前后,缸内温度上升明显。可见,爆震的发生是缸内未燃混合气受到缸内高温的影响,诱发混合气自燃导致的。随着点火定时的提前导致缸内温度和压力升高,使缸内未燃混合气异常燃烧的倾向增大,从而使得发动机爆震倾向增大。

3. 结 论

本文基于一台直列四缸非道路自然吸气缸内直喷氢发动机,开展了氢发动机外特性和点火定时对发动机燃烧及爆震特性影响的试验研究,主要结论如下。

1)本试验中氢发动机在外特性特定工况下,随着转速的增加氢发动机的扭矩先增加后减少,在1 500 r/min时扭矩达到最大值147 N·m,最大功率为36.8 kW,达到了标定功率。并且,在外特性曲线下,最高仅为5.36 %,实现了氢发动机的稳定运转。

2)点火定时对氢发动机的燃烧过程有着显著的影响。在最大扭矩点随着点火定时的提前,缸内峰值压力从5.21增大到5.41 MPa,放热率峰值从67.3增大到72.0 J/(℃A)。点火定时的提前,燃烧重心更靠近上止点,燃烧持续期减小,压力升高率峰值增大;而随着点火定时的提前,缸内温度压力迅速升高,导致平均指示压力循环变动率增大。

3)氢发动机的爆震强度随着点火定时的提前而增大,平均MAPO从0.015增大到0.020 MPa,爆震倾向增大。而且爆震倾向增大的主要原因是点火定时提前导致缸内压力、温度的升高,进而使得未燃混合气异常燃烧的倾向增大,爆震发生倾向增大。

-

图 3 发动机台架示意图

1. 测功机 2. 节气门 3. 缸压传感器 4. 火花塞 5. 氢喷嘴 6. 氧传感器7. 氢轨 8. 氢气流量计 9.储氢罐

Figure 3. Schematic diagram of an engine test bench

1. Dynamometer 2. Throttle valve 3. Cylinder pressure sensor 4. Spark plug 5. Hydrogen injection nozzle 6. Oxygen sensor 7. Hydrogen rail 8. Hydrogen flow meter 9. Hydrogen storage tank

表 1 氢内燃发动机主要结构参数

Table 1 Main structural parameters of hydrogen internal combustion engine

参数Parameters 数值Values 发动机型式

Engine type直列4缸、四冲程、水冷 供氢方式

Hydrogen supply method缸内直喷 喷氢压力

Hydrogen injection pressure/MPa25 缸径

Cylinder bore/mm93 气门数量

Number of valves2 行程

Stroke/mm102 连杆长度

Connecting rod length/mm152 压缩比

Compression ratio10 排量

Displacement/L2.77 标定功率

Rated power/kW36.8 进气门关闭时刻

Intake valve closing angle/℃A−147 排气门开启时刻

Exhaust valve opening angle/℃A140 表 2 台架测控系统主要仪器型号

Table 2 Bench measurement and control system main instrument models

设备名称

Equipment name设备型号Equipment model 电力测功机

Electric dynamometer160 kW 测功机控制系统

Dynamometer control systemPUMAOPEN 2.0 燃烧分析仪

Combustion analyzer631 氢气流量计

Hydrogen flow meterCMFSO15P 表 3 外特性试验工况

Table 3 External characteristic test conditions

转速

Speed/(r·min−1)扭矩

Torque/N·m当量比

Equivalence ratio最佳点火定时

MBT800 123.9 0.80 -9.8 1 200 128.3 0.59 -12.8 1 500 147.0 0.69 -7.5 1 800 146.0 0.67 -5.3 2 200 140.7 0.60 -11.3 2 500 140.6 0.61 -9.8 -

[1] SAZALI N. Emerging technologies by hydrogen: A review[J]. International Journal of Hydrogen Energy, 2020, 45(38): 18753-18771.

[2] 黄粉莲,佘超杰,万明定, 等. 不同海拔下甲醇替代率和主喷正时对RCCI发动机性能的影响[J]. 农业工程学报,2024,40(5):71-81. HUANG Fenlian, YU Chaojie, WAN Dingming, et al. Effects of methanol ratio and main injection timing on the performances of a RCCI engine at different altitudes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(5): 71-81. (in Chinese with English abstract)

[3] ZBIGNIEW S. A comprehensive overview of hydrogen-fueled internal combustion engines: Achievements and future challenges[J]. Energies, 2021, 14(20): 6504. DOI: 10.3390/en14206504

[4] FALFARI S, CAZZOLI G, MARIANI V, et al. Hydrogen application as a fuel in internal combustion engines[J]. Energies, 2023, 16(6): 2545.

[5] 徐功迅,陈伟,方真. 生物质超临界水制氢研究进展[J]. 农业工程学报, 2023, 39(7): 24-35 XU Gongxun, CHEN Wei, FANG Zhen. Research progress of supercritical water hydrogen production from biomass[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(7): 24-35. (in Chinese with English abstract)

[6] DAWOOD F, ANDA M, SHAFIULLAH G M. Hydrogen production for energy: An overview[J]. International Journal of Hydrogen Energy, 2020, 45(7): 3847-3869. DOI: 10.1016/j.ijhydene.2019.12.059

[7] WANG X, SUN B, LUO Q, et al. Visualization research on hydrogen jet characteristics of an outward-opening injector for direct injection hydrogen engines[J]. Fuel, 2020, 280: 118710. DOI: 10.1016/j.fuel.2020.118710

[8] MOHAMMADI A, SHIOJI M, NAKAI Y, et al. Performance and combustion characteristics of a direct injection SI hydrogen engine[J]. International Journal of Hydrogen Energy, 2006, 32(2): 296-304.

[9] LUO Q, HU J, SUN B, et al. Experimental investigation of combustion characteristics and NOx emission of a turbocharged hydrogen internal combustion engine[J]. International Journal of Hydrogen Energy, 2018, 44(11): 5573-5584.

[10] VERHELST S, WALLNER T. Hydrogen-fueled internal combustion engines[J]. Progress in Energy and Combustion Science, 2009, 35(6): 490-527. DOI: 10.1016/j.pecs.2009.08.001

[11] JI C, WANG S, ZHANG B. Effect of spark timing on the performance of a hybrid hydrogen-gasoline engine at lean conditions[J]. International Journal of Hydrogen Energy, 2010, 35(5): 2203-2212. DOI: 10.1016/j.ijhydene.2010.01.003

[12] LUO Q, SUN B. Inducing factors and frequency of combustion knock in hydrogen internal combustion engines[J]. International Journal of Hydrogen Energy, 2016, 41(36): 16296-16305. DOI: 10.1016/j.ijhydene.2016.05.257

[13] DHYANI V, SUBRAMANIAN K A. Experimental investigation on effects of knocking on backfire and its control in a hydrogen fueled spark ignition engine[J]. International Journal of Hydrogen Energy, 2018, 43(14): 7169-7178. DOI: 10.1016/j.ijhydene.2018.02.125

[14] WANG L, LI H, HUANG Z, et al. Impact of hydrogen direct injection on engine combustion and emissions in a GDI engine[J]. Advances in Mechanical Engineering, 2023, 15(9): 16878132231189117.

[15] CHEN W, LU C, ZUO Q, et al. Combustion characteristics analysis and performance evaluation of a hydrogen engine under direct injection plus lean burn mode[J]. Journal of Cleaner Production, 2024, 470: 143323-143323. DOI: 10.1016/j.jclepro.2024.143323

[16] KHALID H A , SAID M F M , VEZA I , et al. Hydrogen port fuel injection: Review of fuel injection control strategies to mitigate backfire in internal combustion engine fuelled with hydrogen[J]. International Journal of Hydrogen Energy, 2024, 66: 571-581.

[17] LI X Y, SUN B G, Zhang D S, et al. Experimental study on the cycle variation characteristics of direct injection hydrogen engine[J]. Energy Conversion and Management: X, 2022, 15: 100260. DOI: 10.1016/j.ecmx.2022.100260

[18] TSUJIMURA T, SUZUKI Y. Development of a large-sized direct injection hydrogen engine for a stationary power generator[J]. International Journal of Hydrogen Energy, 2019, 44(22): 11355-11369. DOI: 10.1016/j.ijhydene.2018.09.178

[19] HUANG Z, YUAN S, WEI H, et al. Effects of hydrogen injection timing and injection pressure on mixture formation and combustion characteristics of a hydrogen direct injection engine[J]. Fuel, 2024, 363: 130966. DOI: 10.1016/j.fuel.2024.130966

[20] FU Z, LI Y, WU W, et al. Experimental study on the combustion and emission performance of the hydrogen direct injection engine[J]. International Journal of Hydrogen Energy, 2024, 61: 1047-1059. DOI: 10.1016/j.ijhydene.2024.02.276

[21] KAWAHARA N, TOMITA E. Visualization of auto-ignition and pressure wave during knocking in a hydrogen spark-ignition engine[J]. International Journal of Hydrogen Energy, 2009, 34(7): 3156-3163. DOI: 10.1016/j.ijhydene.2009.01.091

[22] YANG F, ZHANG H, CHEN Z, et al. Interaction of pressure wave and propagating flame during knock[J]. International Journal of Hydrogen Energy, 2013, 38(35): 15510-15519. DOI: 10.1016/j.ijhydene.2013.09.078

[23] LI Y, GAO W, ZHANG P, et al. Influence of the equivalence ratio on the knock and performance of a hydrogen direct injection internal combustion engine under different compression ratios[J]. International Journal of Hydrogen Energy, 2021, 46(21): 11982-11993. DOI: 10.1016/j.ijhydene.2021.01.031

[24] LAI F Y, SUN B G, WANG X, et al. Research on the inducing factors and characteristics of knock combustion in a DI hydrogen internal combustion engine in the process of improving performance and thermal efficiency[J]. International Journal of Hydrogen Energy, 2023, 48(20): 7488-7498. DOI: 10.1016/j.ijhydene.2022.11.091

[25] LOU D, RAO X, ZHANG Y, et al. Investigation of impacts of hydrogen injection and spark strategy on knock in hydrogen engine[J]. International Journal of Hydrogen Energy, 2024, 82: 1252-1262. DOI: 10.1016/j.ijhydene.2024.08.052

[26] MOHAMMADREZA Y, RAHUL P, MOHSEN T, et al. Numerical investigation of a large bore, direct injection, spark ignition, hydrogen-fuelled engine[J]. International Journal of Hydrogen Energy, 2023, 48(46): 17689-17702.

[27] GALLONI E. Dynamic knock detection and quantification in a spark ignition engine by means of a pressure based method[J]. Energy Conversion and Management, 2012, 64: 256-262. DOI: 10.1016/j.enconman.2012.05.015

[28] SZWAJA S, NABER D J. Dual nature of hydrogen combustion knock[J]. International Journal of Hydrogen Energy, 2013, 38(28): 12489-12496. DOI: 10.1016/j.ijhydene.2013.07.036

[29] WEI H, FENG D, PAN M, et al. Experimental investigation on the knocking combustion characteristics of n-butanol gasoline blends in a DISI engine[J]. Applied Energy, 2016, 175: 346-355. DOI: 10.1016/j.apenergy.2016.05.029

[30] CHEN L, WEI H, PAN J, et al. Understanding the correlation between auto-ignition, heat release and knocking characteristics through optical engines with high compression ratio[J]. Fuel, 2020, 261: 116405-116405. DOI: 10.1016/j.fuel.2019.116405

[31] 卫海桥,王楠,李卫,等. 进气道喷射氢发动机燃烧及爆震特性试验研究[J]. 天津大学学报(自然科学与工程技术版),2022,55(12):1230-1236. WEI Haiqiao, WANG Nan, LI Wei, et al. Experimental Investigations on Combustion and Knock Characteristics of Port Fuel Injection Hydrogen Engine[J]. Journal of Tianjin University(Science and Technology), 2022, 55(12): 1230-1236. (in Chinese with English abstract)

下载:

下载:

下载:

下载: